In the semiconductor manufacturing industry, microscopic contaminants can compromise production yields and device performance. Maintaining ultra-clean air environments isn't just a best practice—it's an absolute necessity. As chip geometries shrink below 7nm and production processes grow more sophisticated, requirements for clean air solutions have become exponentially more stringent. This guide explores the technical requirements, industry standards, and practical considerations for implementing effective clean air solutions in semiconductor manufacturing facilities.

Understanding Semiconductor Clean Air Requirements

Semiconductor fabrication facilities ("fabs") operate in environments demanding unprecedented air purity levels. Modern semiconductor processes are so sensitive to airborne contaminants that standard industrial ventilation systems won't suffice. These contaminants include particulate matter, molecular contaminants, moisture, and static electricity—all of which can harm wafer yields and device reliability.

Cleanrooms in semiconductor manufacturing follow strict classification standards defining allowable particle concentrations. Under ISO 14644-1, semiconductor cleanrooms typically require Class 1 to Class 10 classifications. A Class 1 environment permits no more than one particle (0.5 micrometers or larger) per cubic meter of air. This standard exceeds pharmaceutical manufacturing or medical device production requirements, highlighting the unique challenges of semiconductor clean air management compared to other precision industries like pharmaceutical compression standards.

Particulate contamination control is just one aspect of semiconductor clean air requirements. Equally critical is controlling molecular contaminants (AMCs) like volatile organic compounds (VOCs), acids, bases, and dopant gases. These contaminants can cause wafer surface defects, oxide layer degradation, equipment corrosion, and changes to electrical properties in finished devices.

Key Industry Standards and Certifications

The semiconductor industry follows a comprehensive framework of standards governing clean air requirements, ensuring consistency and quality across global manufacturing operations. These standards address everything from air particle counts and filtration efficiency to compressed air purity and monitoring protocols.

ISO 14644-1 serves as the foundational standard for cleanroom classification, establishing air cleanliness levels based on particle concentration limits. Advanced semiconductor manufacturing facilities typically operate at ISO Class 5 or better—equivalent to Federal Standard 209E Class 100 or cleaner environments. This means maintaining fewer than 100 particles (0.5μm or larger) per cubic foot of air, requiring sophisticated air handling systems and rigorous monitoring protocols.

For compressed air systems, the ISO 8573 standard series provides critical guidance. ISO 8573-1:2010 specifies purity classes for particles, water, and oil. The highest purity level, Class O, represents the gold standard for oil-free compressed air, requiring complete absence of oil in aerosol, liquid, and vapor forms. This standard has become increasingly relevant for semiconductor applications as manufacturers eliminate potential contamination sources entirely.

While semiconductor requirements exceed those of many other industries, understanding comparative standards provides valuable context. For instance, medical grade air compressors focus primarily on human respiratory safety, while food industry air compressors prioritize preventing product contamination. In contrast, semiconductor applications demand the highest levels of particulate and molecular contamination control across all manufacturing processes.

Beyond international standards, semiconductor manufacturers must comply with SEMI Standards developed specifically for the industry. SEMI F21 addresses air and gas filtration systems, while SEMI S2 outlines safety guidelines for semiconductor manufacturing equipment—including those related to air quality and contamination control. These standards update regularly to keep pace with technological advancements and emerging industry needs.

Technical Components of Semiconductor Clean Air Systems

Effective clean air solutions for semiconductor manufacturing integrate multiple technological components working together to maintain required purity levels. These systems address specific contamination challenges while optimizing energy efficiency—a critical consideration given the substantial operational costs of semiconductor fabs.

High-Efficiency Filtration Systems form the first line of defense against particulate contamination. Ultra-Low Penetration Air (ULPA) filters, which achieve 99.999% efficiency for particles 0.12μm and larger, have become standard in advanced semiconductor facilities. These filters typically install in ceiling-mounted fan filter units (FFUs) that create vertical laminar airflow, sweeping contaminants downward and out of critical processing zones.

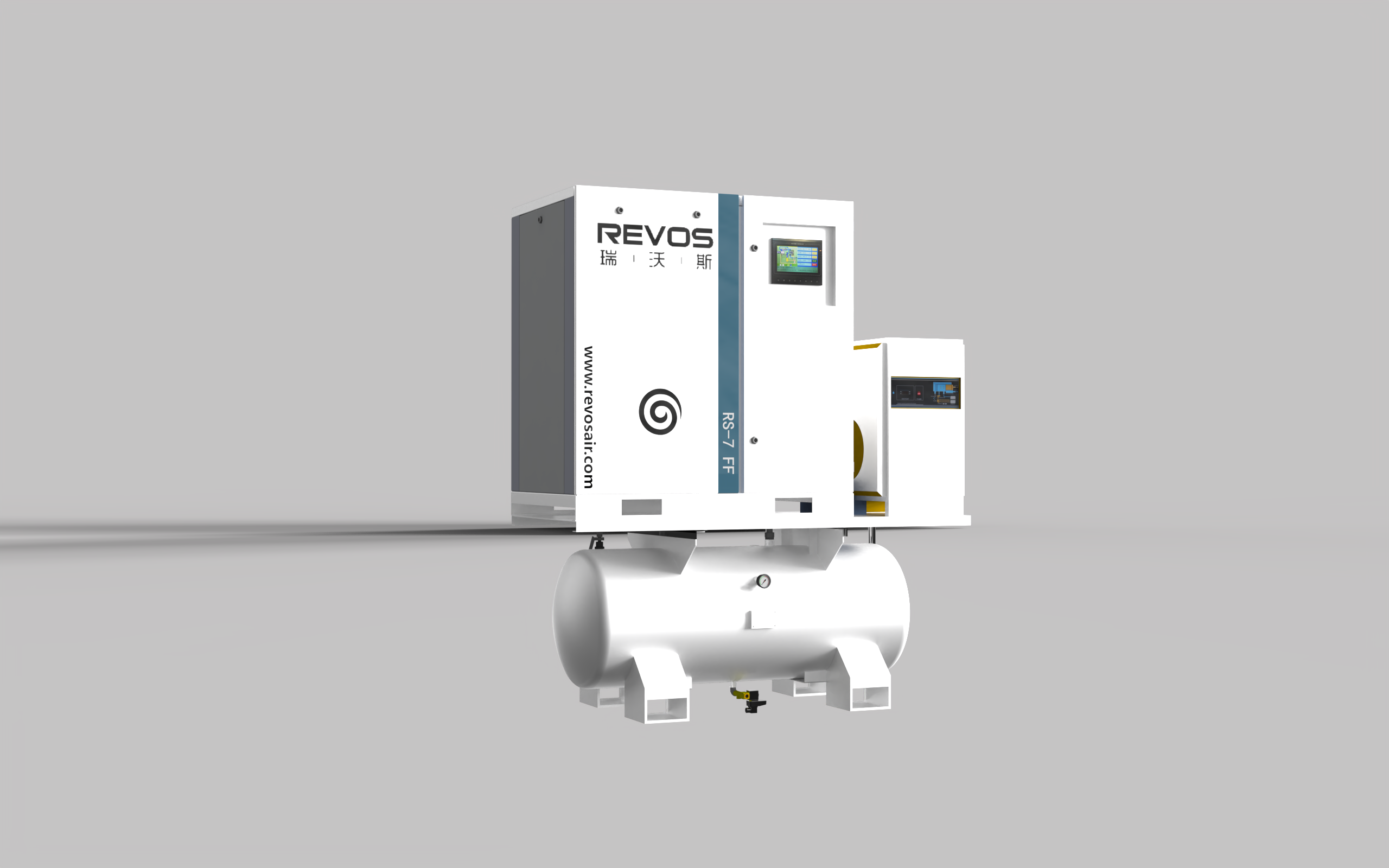

Compressed Air Treatment Systems play a vital role in semiconductor manufacturing. Compressed air supports numerous applications including pneumatic tools, process gas delivery, and wafer handling. Oil-free compressors have become essential, with Class 0 certified systems representing the industry benchmark. These hygienic air compression systems incorporate multiple filtration stages—including coalescing filters, activated carbon adsorbers, and membrane dryers—to achieve required purity levels.

Environmental Monitoring Systems provide continuous verification of air quality parameters throughout the fab. These systems use laser particle counters, gas analyzers, and humidity sensors strategically placed throughout the facility. Collected data feeds into centralized monitoring platforms that trigger alarms and automated responses when parameters deviate from specified limits, ensuring rapid corrective action.

Airflow Management is another critical technical component. Modern fabs use computational fluid dynamics (CFD) modeling to optimize air distribution patterns. This includes designing air returns to minimize turbulence, strategically placing air showers and pass-through chambers, and implementing pressure differentials between adjacent cleanroom zones to prevent cross-contamination.

Emerging Trends and Technological Innovations

The semiconductor clean air solutions market evolves rapidly, driven by advancing process technologies and increasing sustainability requirements. Several key trends are reshaping clean air management in semiconductor manufacturing facilities.

Energy Efficiency has emerged as a primary focus area. Cleanroom HVAC systems typically account for 30-40% of a fab's total energy consumption. Innovations in variable air volume (VAV) systems, energy recovery wheels, and smart airflow control algorithms help manufacturers reduce energy usage while maintaining air quality standards. Some advanced facilities have reported energy savings of up to 38% through optimized air handling designs and process integration.

Digitalization and Smart Monitoring are transforming clean air management through Internet of Things (IoT) sensor networks and artificial intelligence (AI) analytics. These systems enable predictive maintenance of filtration systems, adaptive control of airflow based on real-time process conditions, and advanced contamination source tracking. The global market for semiconductor clean air monitoring systems is projected to grow at a CAGR of 7.2% from 2025 to 2033, reflecting increasing industry investment in these technologies.

Advanced Filtration Materials are pushing contamination control boundaries. Next-generation nanofiber filters offer enhanced particle capture efficiency at lower pressure drops. Novel adsorbent materials provide superior removal of specific molecular contaminants. These advancements are particularly critical for emerging processes like EUV lithography and 3D chip stacking, which introduce new contamination challenges.

Modular Cleanroom Designs are gaining traction, allowing more flexible and cost-effective facility expansions or reconfigurations. These designs incorporate pre-fabricated cleanroom modules with integrated air handling systems, reducing construction time and minimizing disruption to ongoing production. Modular approaches also facilitate more targeted upgrades to clean air systems as specific process requirements evolve.

Selection Criteria for Semiconductor Clean Air Solutions

Selecting appropriate clean air solutions for semiconductor manufacturing facilities requires systematic evaluation of multiple factors. Buyers must balance technical performance requirements with operational efficiency and total cost of ownership. This decision process is particularly complex given semiconductor facilities' long operational lifespans and rapid evolution of clean air technologies.

Purity Requirements Matching stands as the foundational selection criterion. Solutions must be tailored to the specific cleanliness class required for each manufacturing zone. This involves particle count considerations and control of molecular contaminants relevant to specific processes. For example, copper interconnect processes may require specialized filtration for ammonia and amines, while photolithography areas need strict control of volatile organic compounds.

Energy Efficiency Metrics have become increasingly important in selection decisions. Lifecycle energy costs often outweigh initial capital expenditures. Key metrics include specific fan power (SFP), air-to-air energy recovery efficiency, and the system's ability to modulate airflows based on production demands. Manufacturers should also consider integration potential with on-site renewable energy sources.

Reliability and Maintainability are critical factors given semiconductor fabs' continuous operation requirements. Evaluate solutions based on mean time between failures (MTBF), ease of filter replacement, and availability of local service support. Remote monitoring capabilities and predictive maintenance features can significantly reduce downtime and maintenance costs over the system's lifetime.

Scalability and Future-Proofing deserve careful consideration. Clean air systems must accommodate both production volume increases and process technology advancements. Modular designs allowing staged capacity expansions and flexible configuration options provide greater long-term value. Evaluate systems based on their ability to meet future regulatory requirements and more stringent purity standards.

Total Cost of Ownership (TCO) analysis goes beyond upfront purchase price. Include installation costs, energy consumption, maintenance expenses, filter replacement requirements, and eventual disposal or upgrade costs. Comprehensive TCO evaluation typically reveals that higher-performance systems with greater initial investment often provide superior long-term value through lower operating costs and extended service life.

Implementation Best Practices and Case Studies

Successful implementation of semiconductor clean air solutions requires a strategic approach encompassing design, installation, commissioning, and ongoing management. Industry best practices and real-world case studies provide valuable insights for manufacturers embarking on cleanroom construction or upgrade projects.

Phased Implementation Strategies have proven effective for minimizing production disruption during clean air system upgrades. One major semiconductor manufacturer in New Mexico implemented an $18 million clean air system retrofit over 18 months using a phased approach that maintained 95% production uptime. This involved constructing temporary barriers between operational and construction zones, implementing rigorous contamination control protocols for construction activities, and scheduling major system transitions during planned maintenance windows.

Performance Validation and Commissioning represent critical post-installation phases. Best practices include third-party certification of cleanroom classification, comprehensive particle count mapping, and challenge testing with surrogate contaminants to verify filtration efficiency. One leading semiconductor foundry implemented continuous commissioning involving 24/7 monitoring for two weeks following system installation, allowing fine-tuning of airflow patterns and pressure differentials before full production ramp-up.

Staff Training and Protocol Development are essential for maintaining clean air system performance over time. Successful programs typically include specialized training for maintenance personnel on filter replacement procedures, contamination control protocols for equipment access, and emergency response procedures for system upsets. One Asian semiconductor manufacturer reported a 40% reduction in contamination-related incidents after implementing a comprehensive staff training program with simulation exercises and certification requirements.

Continuous Improvement Programs have become standard practice in leading semiconductor facilities. These programs use data from continuous monitoring systems to identify performance trends, optimize maintenance schedules, and implement incremental improvements. For example, a West Coast semiconductor plant implemented an energy optimization program analyzing clean air system data alongside production schedules, resulting in a 15% reduction in energy consumption while maintaining process yields.

Integration with Overall Facility Management represents a best practice gaining traction across the industry. By integrating clean air system data with broader facility management platforms, manufacturers optimize interactions between HVAC systems, process equipment, and environmental controls. This holistic approach has enabled some facilities to achieve significant efficiency gains and better contamination source tracking.

Conclusion: Future Outlook for Semiconductor Clean Air Solutions

As semiconductor manufacturing advances toward smaller process nodes and more complex device architectures, clean air solutions will grow increasingly important. The industry faces the dual challenge of meeting more stringent purity requirements while reducing energy consumption and environmental impact—driving continued innovation in clean air technologies and management practices.

Looking ahead to 2025 and beyond, several key developments will shape semiconductor clean air solutions. Ongoing miniaturization of semiconductor devices will push particle size requirements below current detection limits, requiring advancements in both filtration technologies and monitoring capabilities. Meanwhile, the industry's growing sustainability focus will drive further innovations in energy-efficient air handling, materials recovery, and circular economy approaches to cleanroom operation.

Integration of artificial intelligence and machine learning into clean air management systems will accelerate, enabling predictive maintenance, adaptive control, and more sophisticated contamination source identification. These smart systems will improve air quality control and provide valuable insights for process optimization and yield improvement.

For industrial buyers and facility managers, the rapidly evolving landscape demands a strategic approach to technology evaluation and selection. By prioritizing systems offering current performance and future scalability, energy efficiency, and smart monitoring capabilities, manufacturers can meet the clean air challenges of tomorrow's semiconductor technologies.

Ultimately, semiconductor clean air solutions aim beyond compliance—it's about creating an environment enabling reliable, efficient production of advanced semiconductor devices powering our modern digital world. Investment in state-of-the-art clean air systems represents not just a manufacturing necessity but a strategic enabler of technological progress.