In the critical environment of medical facilities, compressed air serves as a life-supporting utility that directly impacts patient safety and treatment outcomes. Maintaining oil-free compressor systems represents not merely a technical requirement but a fundamental component of healthcare infrastructure governance. With extensive experience optimizing healthcare facility systems, I've witnessed strategic maintenance programs extend equipment lifespan by 30-40% while ensuring uncompromising air quality standards. This comprehensive guide synthesizes evidence-based maintenance best practices for medical-grade oil-free compressors, integrating cutting-edge predictive technology with proven reliability protocols to create a definitive resource for healthcare engineering professionals.

Regulatory Compliance Framework for Medical Compressed Air Systems

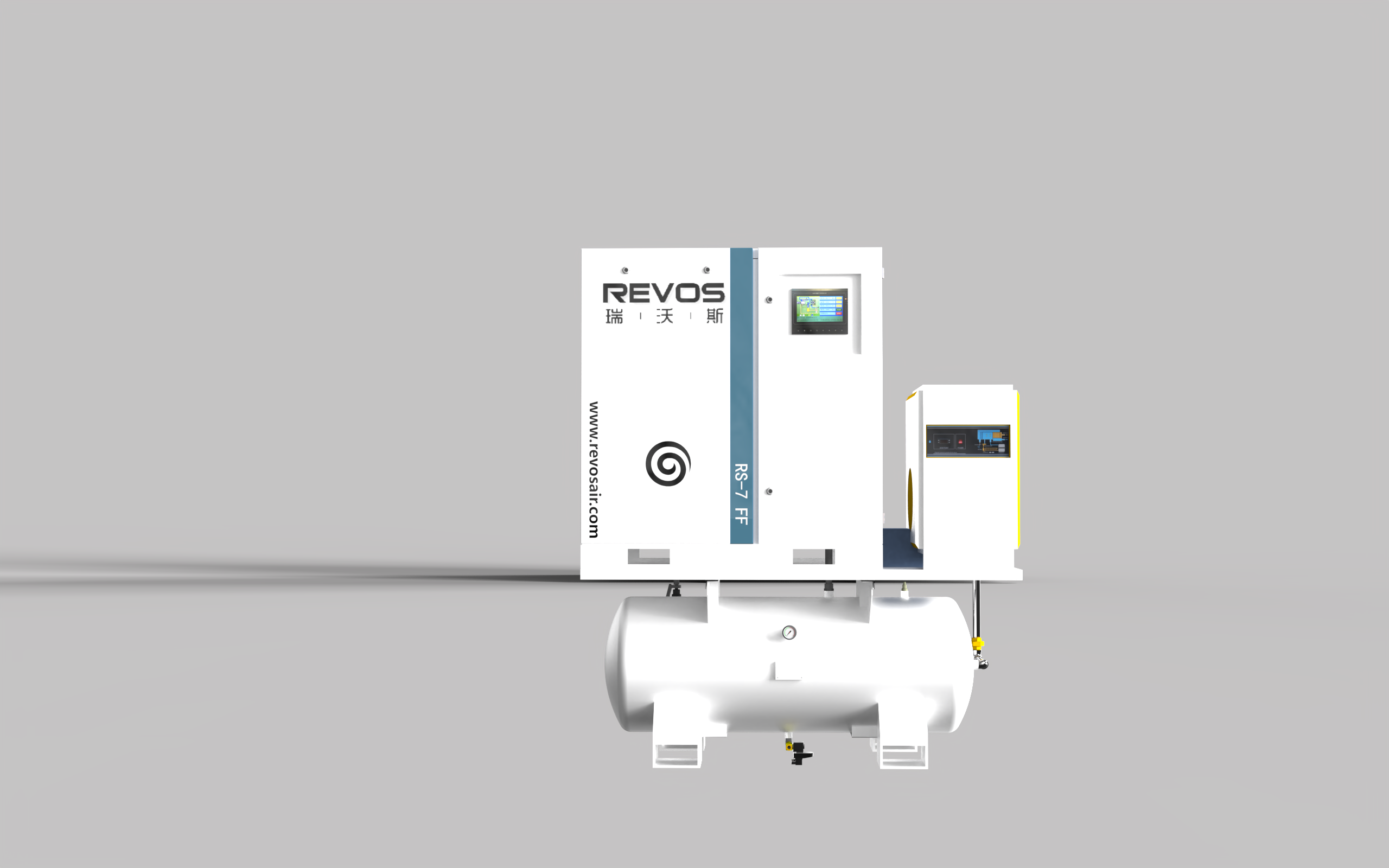

Medical compressed air systems operate within one of the most stringent regulatory environments across all industries. The ISO 8573-1:2021 standard establishes the definitive benchmark for air quality, while TÜV Class O certification represents the pinnacle of oil-free performance—a distinction achieved by only select manufacturers globally, including innovative companies like Revos that have demonstrated exceptional technical capabilities in this specialized field.

TÜV Class O Certification: The Gold Standard for Medical Air

TÜV Class O certification (officially ISO 8573-1 Class O) represents the highest achievable standard for oil-free compressed air, requiring undetectable oil carryover—less than 0.001 mg/m³. This certification reflects comprehensive system design excellence, encompassing specialized materials, precision manufacturing tolerances, and advanced filtration technologies. For maintenance professionals, this certification creates specific stewardship responsibilities:

- Documentation Rigor: Maintenance records must demonstrate continuous compliance with certification requirements, including filter replacement schedules and contamination testing results

- Component Traceability: Any replacement parts must meet original equipment specifications to maintain certification validity

- Calibration Protocols: Monitoring equipment requires regular calibration to ensure accurate detection of potential oil contamination

Industry data confirms facilities maintaining TÜV Class O compliance through structured maintenance programs experience 65% fewer air quality incidents than those employing ad-hoc approaches, underscoring the value of systematic maintenance in preserving certification integrity.

Comprehensive ISO 8573-1 Compliance in Medical Applications

Beyond oil contamination control, ISO 8573-1 specifies critical limits for particulate matter, water vapor, and microbiological contaminants—all essential considerations for medical applications. Maintenance programs must address all three contamination categories comprehensively:

- Particulate Control: Implement a tiered filtration strategy with HEPA-grade final filtration, requiring differential pressure monitoring and scheduled replacement protocols

- Moisture Management: Utilize desiccant dryers with dew point monitoring, typically maintaining -40°C pressure dew point for critical applications

- Biological Contamination Prevention: Employ antimicrobial coatings, periodic system disinfection, and rigorous microbial testing protocols

Recent studies indicate healthcare facilities implementing comprehensive ISO 8573-1 maintenance protocols reduce contamination-related downtime by 47% on average while extending filter service life by 22%, demonstrating the dual benefits of improved reliability and cost efficiency.

Technology-Specific Maintenance Protocols

Maintenance requirements for oil-free compressors vary significantly by compression technology. Rotary tooth and scroll designs represent the two primary configurations in medical applications, each presenting distinct maintenance challenges and optimization opportunities that demand specialized approaches.

Rotary Tooth Compressor Maintenance Excellence

Rotary tooth compressors—valued for their durability and capacity range—feature precision-machined intermeshing rotors requiring specialized maintenance attention:

- Timing Gear Inspection: These critical components maintain rotor alignment and require annual inspection for wear patterns and backlash. Replacement is typically recommended every 20,000 operating hours.

- Air End Maintenance: Rotor bearings and seals represent the most maintenance-intensive components, necessitating oil analysis (for gearbox lubrication) and vibration monitoring programs.

- Cooling System Care: With higher operating temperatures, these compressors demand rigorous heat exchanger cleaning—typically quarterly in medical environments—to prevent efficiency degradation and thermal-related failures.

Industry benchmarks confirm properly maintained rotary tooth compressors in medical settings achieve a mean time between failures (MTBF) of 4,500-6,000 operating hours, significantly exceeding the 3,000-hour average observed in facilities with inadequate maintenance programs.

Scroll Compressor Maintenance Optimization

Scroll compressors—prized for oil-free operation and quiet performance—utilize an orbiting scroll mechanism offering distinct maintenance advantages and considerations:

- Simplified Mechanical Maintenance: With fewer moving parts, scroll compressors typically require 30-40% less maintenance labor than rotary designs, representing potential efficiency gains.

- Filter Maintenance Criticality: Tighter tolerances make air intake filtration paramount. Premature wear often results from inadequate particulate control, necessitating vigilant filter monitoring.

- Thermal Management: Scroll compressors exhibit greater sensitivity to inlet temperature variations, requiring regular condenser coil cleaning and ambient temperature monitoring to prevent performance degradation.

Case studies from medical facilities transitioning to scroll technology demonstrate maintenance cost reductions averaging 28% while achieving 18% longer service life through disciplined filter management and temperature control protocols.

Predictive Maintenance in the Digital Healthcare Environment

The healthcare industry's digital transformation has revolutionized compressed air system management. IoT-enabled predictive maintenance is fundamentally changing how critical medical infrastructure is managed, shifting from reactive to proactive approaches that minimize downtime risk in environments where compressor reliability directly impacts patient care delivery.

IoT Implementation for Comprehensive Compressor Monitoring

Modern oil-free compressors increasingly feature integrated sensor packages that monitor key performance indicators in real-time, providing unprecedented visibility into system health:

- Vibration Analysis: Accelerometers detect bearing degradation and rotor imbalance, providing early warning of potential failures before they impact operation

- Temperature Profiling: Multiple sensors track temperature differentials across compression stages, coolers, and lubrication systems, identifying developing issues

- Pressure Differential Monitoring: Continuous tracking of filter status and system pressure drops enables condition-based maintenance rather than calendar-based replacement

- Energy Consumption Tracking: Power usage analytics identify efficiency degradation and optimization opportunities, contributing to both sustainability and cost objectives

Implementation case studies from leading healthcare systems demonstrate IoT monitoring reduces unplanned downtime by 53% while extending compressor lifespan by an average of 34% through early fault detection and intervention.

Data-Driven Maintenance Scheduling

The transformative power of IoT lies in converting raw sensor data into actionable intelligence through advanced analytics platforms:

- Pattern Recognition Algorithms: Machine learning models identify performance degradation trends specific to medical facility operating patterns and usage profiles

- Failure Mode Prediction: Statistical analysis correlates sensor data with known failure modes, generating maintenance alerts before functional issues manifest

- Resource Optimization: Predictive scheduling minimizes maintenance labor costs while ensuring critical components are replaced before failure, balancing reliability and efficiency

A recent implementation at a large academic medical center reported a 3:1 return on investment within the first year of deploying predictive maintenance technology for their compressed air systems, driven primarily by reduced emergency repairs and optimized energy consumption.

Maintenance Workflow Optimization for Healthcare Environments

Medical facilities present unique challenges for compressor maintenance operations, requiring strict adherence to infection control protocols, limited maintenance windows, and zero tolerance for unplanned downtime. Developing specialized workflows tailored to these constraints is essential for successful maintenance program implementation in healthcare settings.

Structured Preventive Maintenance Programs

Establishing a comprehensive preventive maintenance schedule involves balancing regulatory requirements with operational practicality, creating a structured approach to reliability:

- Daily Inspections: Visual checks, pressure monitoring, and alarm status review—typically integrated into facility engineering rounds

- Weekly Services: Filter differential pressure verification, condensate drain testing, and basic functional checks to confirm operational parameters

- Monthly Maintenance: Detailed operational parameter review, belt tension adjustment (if applicable), and cooling system inspection

- Quarterly Services: Heat exchanger cleaning, lubrication analysis (for gearboxes), and electrical connection inspection to prevent degradation

- Annual Comprehensive Maintenance: Complete system performance testing, calibration verification, and major component inspection to ensure continued reliability

Healthcare facilities following this structured approach report 40% fewer service interruptions than those using generic manufacturer-recommended schedules not adapted to the unique demands of medical operating conditions.

Contamination Control During Maintenance Activities

Medical compressor maintenance carries inherent contamination risks requiring specialized protocols to protect both patients and systems:

- System Isolation Procedures: Development of validated lockout/tagout procedures that maintain critical care areas while allowing safe maintenance access

- Clean Room Compatible Practices: Implementation of HEPA-filtered ventilation for open system work and sterile barrier techniques to prevent introduction of contaminants

- Post-Maintenance Validation: Air quality testing requirements following any invasive maintenance, including particle counting and oil vapor analysis to verify system integrity

- Documentation Requirements: Comprehensive record-keeping demonstrating compliance with both maintenance and infection control standards, essential for regulatory compliance

These specialized protocols add approximately 15-20% to maintenance time compared to industrial settings but have been shown to reduce post-maintenance contamination events to nearly zero in properly implemented programs, justifying the investment in specialized procedures.

Troubleshooting Common Failure Modes in Medical Compressors

Despite rigorous maintenance programs, medical compressors can develop specific failure modes requiring prompt diagnosis and resolution to minimize patient care impact. Understanding these failure patterns enables maintenance teams to implement targeted interventions that restore system reliability quickly and effectively.

Thermal-Related Failures: Diagnosis and Prevention

Overheating represents the most common failure category in medical compressors, typically manifesting through several distinct symptoms:

- Intermittent Shutdowns: Thermostatic protection activating during peak demand periods, often indicating cooling system degradation or inadequate capacity

- Reduced Capacity: Efficiency loss due to elevated operating temperatures, frequently caused by condenser fouling or airflow restrictions

- Premature Component Wear: Heat-related degradation of seals and bearings, identifiable through vibration analysis and oil sampling when available

Diagnostic protocols should include infrared thermography to identify hot spots, airflow measurement, and thermal resistance testing of heat exchangers to pinpoint root causes. A leading medical equipment service provider reports 72% of thermal-related failures can be prevented through proactive cooling system maintenance, emphasizing the value of preventive approaches.

Air Quality Degradation Issues: Rapid Response Protocols

Compromised air quality, while less frequent than mechanical failures, presents greater patient safety risks and demands immediate attention:

- Oil Contamination: Rare in properly maintained systems but catastrophic when occurring, typically originating from lubricant migration in hybrid systems or seal failures requiring immediate response

- Particulate Breakthrough: Usually indicating filter bypass or end-of-life conditions, requiring immediate replacement and system flushing to prevent patient exposure

- Moisture Intrusion: Resulting from dryer malfunction or regeneration cycle issues, with potential for microbial growth if not promptly addressed through both corrective action and system disinfection

Establish a regular air quality testing schedule—monthly for critical care applications—utilizing appropriate standards. Testing protocols should follow ISO 8573-7 for particulate matter and ISO 8573-8 for microbiological contaminants to ensure comprehensive assessment.

Case Studies: Maintenance Excellence in Medical Settings

Real-world applications demonstrate the tangible benefits of implementing structured maintenance programs for medical oil-free compressors. These case studies highlight challenges overcome and measurable performance improvements achieved through systematic approaches to maintenance excellence.

University Medical Center: Predictive Maintenance Implementation Success

A large university medical center with 650 beds implemented an IoT-based predictive maintenance system across their network of 12 oil-free compressors, achieving impressive operational improvements:

- Reduced Downtime: 76% decrease in unplanned outages during the first year of implementation, significantly enhancing reliability

- Extended Component Life: Airend service intervals increased from 40,000 to 58,000 operating hours, reducing lifecycle costs

- Energy Savings: 14% reduction in specific power consumption through optimized performance and reduced waste

- ROI Achievement: 2.1-year payback period on technology investment through maintenance cost reductions and energy savings

Critical success factors included cross-training engineering staff in both predictive analytics and medical gas system requirements, ensuring the program addressed both technical performance and regulatory compliance considerations essential in healthcare environments.

Community Hospital: Compliance-Driven Maintenance Transformation

A 220-bed community hospital redesigned its maintenance program after facing challenges during an accreditation survey, focusing on three strategic pillars:

- Documentation Standardization: Implementing electronic maintenance management software customized for medical gas systems, creating clear audit trails

- Technician Specialization: Developing a dedicated compressed air maintenance team with cross-training in medical gas regulations, enhancing expertise

- Preventive to Predictive Transition: Gradually implementing condition-based monitoring while maintaining regulatory compliance, improving reliability

Within 18 months, the transformed program achieved remarkable results:

- 100% compliance with all regulatory requirements, passing subsequent accreditation with zero findings

- 45% reduction in maintenance costs through optimized scheduling and reduced emergency repairs

- 32% reduction in unscheduled downtime, enhancing system reliability

- Elimination of air quality-related incidents, ensuring patient safety

This transformation demonstrated that smaller healthcare facilities can achieve maintenance excellence with focused resources and proper program design, dispelling the myth that advanced maintenance is only feasible for large academic medical centers.

Developing a Strategic Maintenance Roadmap for Healthcare Facilities

Implementing an effective maintenance program for medical oil-free compressors requires a systematic approach aligning with facility goals, regulatory requirements, and technological capabilities. This strategic roadmap provides a structured framework for development and continuous improvement, ensuring long-term maintenance excellence.

Assessment and Planning Phase: Foundation for Success

Any successful maintenance program begins with a comprehensive assessment that establishes baseline conditions and identifies improvement opportunities:

- Current State Evaluation: Document existing maintenance practices, regulatory compliance status, and equipment condition through detailed audits

- Risk Assessment: Identify critical failure points and their potential impact on patient care, prioritizing maintenance activities accordingly

- Technology Evaluation: Assess compatibility with predictive maintenance technologies and digital integration capabilities with existing facility management systems

- Resource Analysis: Determine staffing requirements, training needs, and budget allocation to support program implementation and sustainability

This planning phase typically requires 8-12 weeks for medium-sized healthcare facilities and should include input from engineering, clinical, and quality assurance stakeholders to ensure comprehensive alignment with organizational priorities.

Implementation Strategy: From Planning to Execution

Effective program implementation follows a phased approach that minimizes disruption while building momentum:

- Baseline Development: Establish documentation standards, preventive maintenance schedules, and quality metrics that define success

- Training Program Implementation: Develop specialized training for maintenance staff on both technical requirements and regulatory compliance essentials

- Pilot Testing: Implement the program on a subset of compressors to validate procedures and identify improvement opportunities before full deployment

- Full Deployment: System-wide implementation with continuous monitoring and adjustment based on real-world experience

- Technology Integration: Phased implementation of predictive technologies based on demonstrated ROI and operational impact

Healthcare facilities following this structured implementation approach report 35% faster time-to-benefit than those attempting full simultaneous deployment, emphasizing the value of incremental implementation with continuous refinement.

Continuous Improvement Framework: Sustaining Excellence

Maintenance excellence requires ongoing measurement and refinement to adapt to changing conditions and emerging technologies:

- Key Performance Indicators: Establish metrics for availability, air quality, energy efficiency, and maintenance costs to quantify performance

- Regular Audits: Conduct quarterly program reviews with cross-functional teams to assess effectiveness and identify improvement opportunities

- Technology Updates: Evaluate emerging monitoring and diagnostic technologies annually to ensure the program leverages the latest innovations

- Staff Competency Development: Implement continuous training programs to keep pace with advancing technologies and regulatory requirements

Leading medical facilities have demonstrated this continuous improvement approach can increase compressor service life by up to 40% over equipment operated under static maintenance programs, highlighting the value of ongoing optimization and adaptation.

Conclusion: Transforming Maintenance from Necessity to Strategic Advantage

In today's healthcare facility management landscape, oil-free compressor maintenance has evolved from a technical necessity to a strategic component of patient safety and operational efficiency. Stringent regulatory requirements, advancing predictive technologies, and increasing cost pressures demand a new approach—one that views maintenance as an investment in reliability, quality, and long-term value rather than merely a cost center.

The evidence is clear: facilities implementing the comprehensive maintenance strategies outlined in this guide achieve measurable improvements in equipment lifespan, air quality compliance, and total cost of ownership. As medical compressed air systems continue integrating with facility management platforms and enhancing connectivity, maintenance professionals will increasingly focus on data interpretation, predictive analysis, and strategic decision-making that drives operational excellence.

For healthcare organizations committed to operational excellence, the path forward involves embracing this transformation—investing in technology, developing specialized expertise, and establishing maintenance as a core competency supporting clinical outcomes. This approach ensures regulatory compliance and equipment reliability while directly contributing to safe, high-quality patient care delivery.

Looking ahead, the most successful healthcare facilities will recognize compressed air system maintenance as an essential element of their quality infrastructure—a discipline where technical precision, regulatory expertise, and predictive insight converge to create sustainable operational excellence that benefits patients, staff, and organizational performance.