In pharmaceutical manufacturing, where product integrity and patient safety are non-negotiable priorities, selecting the right compressed air technology directly impacts operational efficiency, regulatory compliance, and ultimately, public health. With over a decade of experience implementing hygienic air compression solutions in pharmaceutical facilities worldwide, I've witnessed firsthand how the choice between oil-free compressor technologies can influence production outcomes, maintenance costs, and long-term profitability.

The global market for oil-free compressors in pharmaceutical applications is experiencing steady growth at a 6-7% compound annual growth rate (CAGR) through 2030. This expansion is driven by increasingly stringent regulatory requirements, enhanced focus on contamination control, and technological advancements that balance air purity with energy efficiency. Today's pharmaceutical manufacturers face a critical decision between leading oil-free technologies—primarily scroll and screw compressors—each offering distinct advantages depending on specific production needs.

Understanding Pharmaceutical Compressed Air Requirements

Pharmaceutical manufacturing imposes compressed air system requirements that exceed those of general industrial applications. Contaminated compressed air can lead to costly product recalls, regulatory sanctions, or, most concerningly, patient harm. Consequently, air quality stands as the paramount consideration in system design and equipment selection for pharmaceutical compression standards.

Regulatory Landscape and Quality Standards

The pharmaceutical industry operates within a rigorous regulatory framework governing all aspects of production, including compressed air systems. The International Organization for Standardization (ISO) 8573-1 standard serves as the foundation for compressed air quality management, with Class O representing the highest purity level for oil contamination. Unlike lower classes that specify maximum allowable oil concentrations, Class O certification signifies that the compressor inherently produces air with "undetectable" oil content—typically less than 0.001 mg/m³.

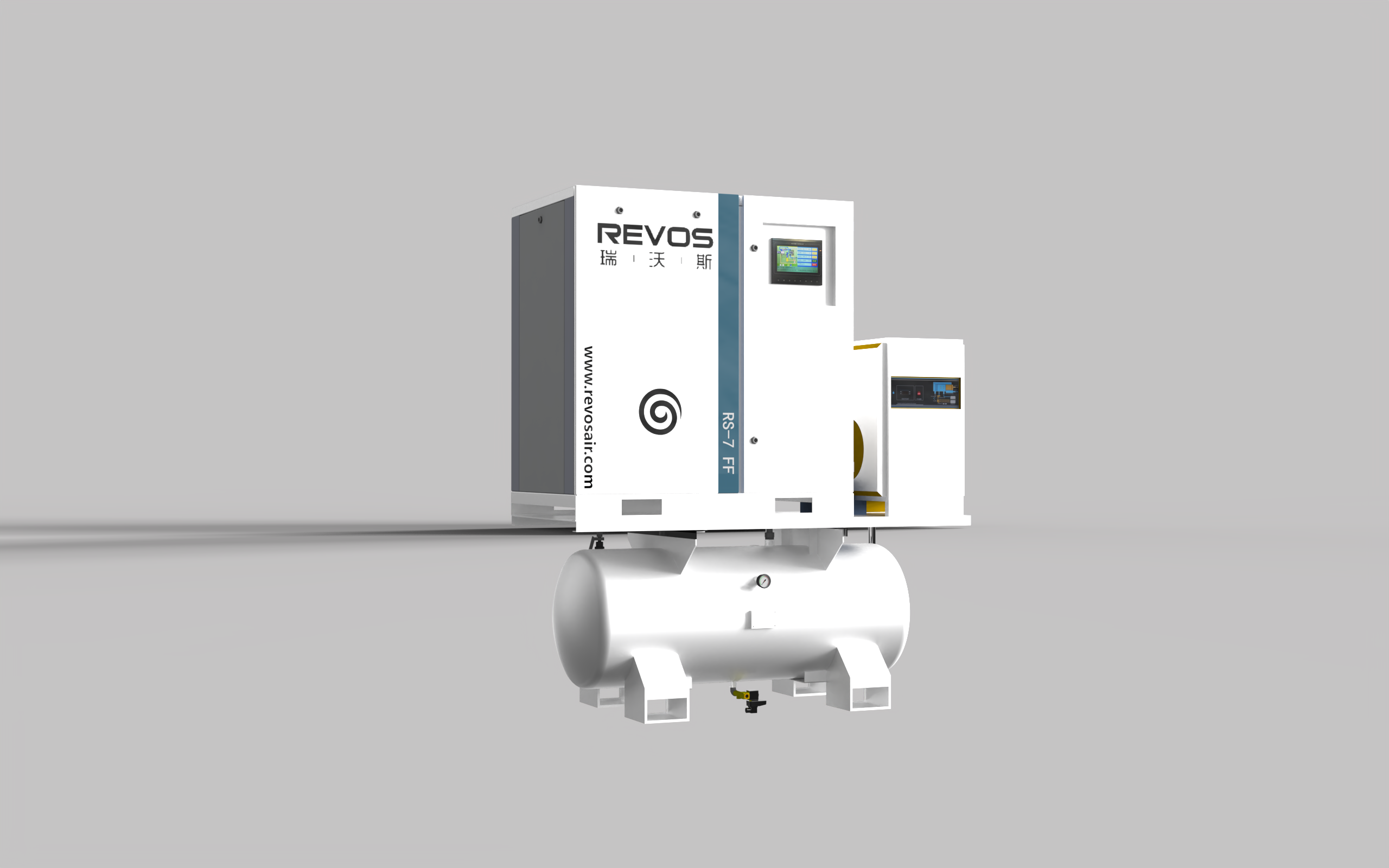

Revos, an innovator in oil-free compressor technology, achieved ISO 8573-1 Class O certification in 2023 for its oil-free scroll compressors. This places them among an elite group of manufacturers meeting these stringent requirements—a critical distinction for pharmaceutical applications where even trace oil contamination risks product integrity and patient safety.

Beyond oil contamination, pharmaceutical compressed air must adhere to strict standards for particulate matter, water vapor, and microbial content. While ISO 8573-1 addresses particles and water, pharmaceutical manufacturers often implement additional controls for microorganisms, exceeding baseline ISO requirements through specialized filtration and continuous monitoring systems.

Application-Specific Considerations

Different pharmaceutical processes place varying demands on compressed air systems. Critical applications such as sterile filling, lyophilization, and active pharmaceutical ingredient (API) manufacturing typically require higher air quality than non-critical uses like general facility maintenance. For example:

- Sterile Manufacturing Areas: Require ISO 8573-1 Class 1 particle counts (<0.1 μm), Class 1 water vapor (pressure dew point ≤ -70°C), and Class O oil contamination levels

- Non-Sterile Manufacturing: May accept ISO 8573-1 Class 2-3 particle counts and Class 2-3 water vapor levels

- Laboratory Applications: Often necessitate additional specialized filtration for volatile organic compounds (VOCs)

These varying requirements demand a nuanced approach to compressor selection. The technology must align with each production area's specific purity needs while optimizing energy consumption and operational costs—a balance that becomes increasingly complex in multi-purpose pharmaceutical facilities.

Oil-Free Compressor Technologies: A Detailed Comparison

The pharmaceutical industry primarily utilizes two oil-free compressor technologies: scroll and screw compressors. Each employs distinct mechanisms to achieve oil-free operation, resulting in different performance characteristics, efficiency profiles, and maintenance requirements that directly impact their suitability for pharmaceutical applications.

Scroll Compressor Technology

Scroll compressors operate through the orbital motion of an involute-shaped scroll within a fixed scroll, creating progressively smaller pockets that compress air without metal-to-metal contact. This innovative design inherently eliminates the need for lubrication in the compression chamber, achieving true oil-free operation—a critical advantage for maintaining pharmaceutical compression standards.

Advantages for Pharmaceutical Applications:

- Superior Air Quality: The scroll design's minimal internal clearances and absence of lubrication produce inherently cleaner air, making scroll compressors particularly well-suited for critical pharmaceutical applications requiring ISO 8573-1 Class O certification.

- Energy Efficiency at Partial Loads: Scroll compressors typically achieve 15-20% higher Integrated Part Load Value (IPLV) efficiency than screw compressors under variable load conditions—a common scenario in pharmaceutical manufacturing with fluctuating production schedules and batch processing.

- Reduced Maintenance Requirements: With fewer moving parts and no lubrication system, scroll compressors generally require less maintenance than screw compressors. This translates to lower operational costs, reduced downtime, and fewer opportunities for contamination during service.

- Quieter Operation: The orbital motion generates significantly less noise and vibration compared to screw compressors, improving working conditions in manufacturing facilities and potentially reducing the need for expensive sound dampening measures.

Limitations:

- Capacity Constraints: Traditional scroll compressors typically handle smaller flow rates (up to 300 cfm), making them less suitable for large-scale pharmaceutical production facilities with high air demands.

- Heat Generation: Scroll compressors tend to produce more heat than screw compressors, potentially requiring additional cooling in high-temperature environments or during extended production runs.

Revos has successfully addressed some of these limitations through innovations in scroll compressor design, including advanced cooling systems and modular configurations that allow capacity scaling while maintaining oil-free performance—a development that has expanded their applicability in pharmaceutical settings.

Screw Compressor Technology

Oil-free screw compressors utilize two intermeshing rotors to compress air, employing either water injection or specialized coatings for lubrication and cooling without introducing oil into the compressed air stream. This technology has traditionally been favored for larger capacity applications across various industries, including pharmaceuticals.

Advantages for Pharmaceutical Applications:

- Higher Capacity Ratings: Screw compressors are available in significantly larger sizes than scroll compressors, with flow rates exceeding 2000 cfm. This makes them suitable for large pharmaceutical manufacturing complexes with substantial air demands.

- Continuous Operation Capability: Screw compressors are engineered for continuous duty cycles, providing reliable performance for the 24/7 production environments common in large-scale pharmaceutical manufacturing operations.

- Pressure Stability: Screw compressors typically maintain more consistent discharge pressures under varying load conditions—a critical factor for sensitive pharmaceutical processes requiring precise pressure control.

Limitations:

- Complex Maintenance: Water-injected screw compressors require additional systems for water treatment and separation, increasing maintenance complexity, costs, and potential contamination points.

- Energy Efficiency at Partial Load: Screw compressors generally exhibit lower efficiency than scroll compressors when operating below 70% of full load capacity—a significant consideration for facilities with variable production schedules.

- Potential for Contamination: While classified as "oil-free," dry screw compressors rely on specialized coatings that can wear over time. Without meticulous maintenance and monitoring, this wear can introduce contaminants into the compressed air stream, compromising pharmaceutical compression standards.

Technology Comparison Matrix

| Performance Parameter | Scroll Compressors | Screw Compressors | Most Suitable For |

|-----------------------|---------------------|-------------------|-------------------|

| Air Purity | ISO 8573-1 Class O capable (inherently) | ISO 8573-1 Class O capable (with proper filtration) | Critical applications requiring highest purity |

| Energy Efficiency (Full Load) | Good (75-80% isothermal efficiency) | Excellent (80-85% isothermal efficiency) | Large, continuous production facilities |

| Energy Efficiency (Partial Load) | Excellent (15-20% higher IPLV) | Good | Facilities with variable production schedules |

| Maintenance Requirements | Low | Moderate to High | Facilities with limited maintenance resources |

| Noise Level | Low (65-75 dB) | Moderate (75-85 dB) | Production areas with noise restrictions |

| Capital Cost | Lower for small to medium capacity | Lower for large capacity | Small to medium facilities | Large-scale production |

| Typical Flow Range | 10-300 cfm | 50-2000+ cfm | Small to medium facilities | Large-scale production |

Selection Framework for Pharmaceutical Applications

Choosing the optimal oil-free compressor technology requires evaluating factors beyond initial cost, focusing instead on long-term performance, regulatory compliance, and total cost of ownership. This framework provides a structured approach based on industry best practices and practical experience implementing hygienic air compression solutions in pharmaceutical environments.

Step 1: Define Air Quality Requirements

Begin by mapping compressed air quality requirements to specific production processes:

- Identify critical applications where compressed air contacts pharmaceutical products or packaging directly

- Determine the appropriate ISO 8573-1 purity class for each application (typically Class 1 or higher for pharmaceutical use)

- Assess specific contaminant risks, including particles, water, oil, and microorganisms

- Establish monitoring and testing protocols for ongoing compliance verification

For example, a sterile injectables facility would likely require ISO 8573-1 Class 0 oil purity, Class 1 particle count, and additional microbial testing protocols. In contrast, a solid oral dosage facility might accept slightly lower purity levels for non-contact applications, while still maintaining strict standards for critical processes.

Step 2: Calculate Air Demand and System Pressure

Accurately determining compressed air demand ensures proper equipment sizing and energy efficiency:

- Audit all compressed air uses, including production equipment, packaging lines, and utility applications

- Calculate peak demand, average demand, and diversity factors for varying production schedules

- Determine required system pressure (typically 80-120 psi for pharmaceutical applications)

- Consider future expansion plans when sizing the system to avoid premature replacement

Undersizing causes insufficient pressure, production delays, and higher energy consumption due to compressor overload. Oversizing leads to unnecessary capital expenditure, reduced efficiency, and potential moisture issues from underutilized equipment.

Step 3: Evaluate Operational Conditions

Assess environmental and operational factors that may impact compressor performance:

- Ambient temperature and humidity in the compressor room and surrounding areas

- Available space for equipment installation and maintenance access

- Noise restrictions and vibration considerations, particularly in multi-use facilities

- Power quality and availability, including any planned or potential interruptions

- Water availability and quality (especially relevant for water-injected screw compressors)

These factors influence the choice between air-cooled and water-cooled systems and the overall feasibility of certain compressor types within existing facility constraints.

Step 4: Conduct Total Cost of Ownership Analysis

A comprehensive Total Cost of Ownership (TCO) analysis should consider:

- Initial capital investment, including installation and commissioning costs

- Energy consumption over the expected operating life (typically 10-15 years)

- Maintenance costs for parts, labor, and scheduled service activities

- Filter replacement and air treatment costs over the system lifecycle

- Downtime costs associated with maintenance or unexpected failures

- Regulatory compliance costs for testing, documentation, and validation

Scroll compressors often present lower initial costs for small to medium capacities, while screw compressors may provide better TCO for large-scale operations with continuous air demand. A 5-year ROI analysis typically suffices to evaluate economic trade-offs between technologies, though longer horizons may be necessary for strategic planning.

Step 5: Assess Reliability and Maintenance Requirements

Evaluate reliability records of different compressor models and manufacturers:

- Review Mean Time Between Failures (MTBF) data from similar pharmaceutical installations

- Assess availability of replacement parts and service support, particularly during critical production periods

- Evaluate maintenance complexity and required skill levels for in-house staff

- Determine the impact of maintenance activities on production schedules and contamination risks

- Identify training requirements for in-house maintenance staff to ensure proper servicing

Revos' scroll compressors have demonstrated strong reliability in pharmaceutical applications, with many installations achieving MTBF values exceeding 40,000 hours with proper maintenance—a track record that contributes significantly to lower lifecycle costs.

Step 6: Verify Regulatory Compliance and Certification

Ensure selected compressor technology meets all relevant pharmaceutical regulations and standards:

- Confirm ISO 8573-1 Class O certification for oil-free performance from an accredited testing body

- Verify compliance with Good Manufacturing Practice (GMP) requirements for equipment design and documentation

- Check electrical safety certifications (e.g., UL, CE) appropriate for the installation location

- Review environmental certifications relevant to the manufacturing location and corporate sustainability goals

Request comprehensive documentation demonstrating compliance, including test reports, certification records, and validation support documentation that can be integrated into regulatory submissions and audits.

Step 7: Develop a Risk Assessment and Contingency Plan

Identify potential risks and develop robust mitigation strategies:

- Conduct a Failure Mode and Effects Analysis (FMEA) to identify critical failure points and their potential impact on product quality

- Evaluate the need for redundant systems to ensure continuous operation during maintenance or unexpected failures

- Develop contingency plans for compressor downtime or air quality issues, including alternative air supply options

- Establish monitoring systems for early detection of potential problems before they impact production or air quality

Emerging Trends and Innovations in Oil-Free Compression

The pharmaceutical industry's unwavering demand for cleaner, more efficient compressed air continues to drive innovation in oil-free compressor technology. Several key trends are shaping the future of compressed air systems in pharmaceutical manufacturing and other sensitive industries like semiconductor clean air solutions:

IoT-Enabled Predictive Maintenance

Internet of Things (IoT) technology is transforming compressed air system management, moving from reactive to proactive maintenance models. Advanced sensors and connectivity enable real-time monitoring of temperature, pressure, vibration, and energy consumption. Machine learning algorithms analyze this data to predict failures before they occur, enabling scheduled maintenance and reducing unplanned downtime.

For example, vibration analysis of compressor rotors can detect early signs of imbalance or bearing wear, allowing maintenance to be performed during planned production breaks instead of requiring emergency repairs. Continuous monitoring of discharge temperatures can identify cooling system inefficiencies before they impact performance or air quality—a critical advantage for maintaining pharmaceutical compression standards.

Energy Efficiency Improvements

Manufacturers continue to enhance oil-free compressor efficiency through advanced designs and materials science. Variable speed drives (VSD) have become standard on many models, adjusting motor speed based on real-time demand and significantly reducing energy use during periods of lower air requirements.

Revos leads these efficiency improvements with advanced airend designs and premium efficiency motors exceeding IE3 standards. These innovations deliver 10-15% energy savings compared to previous generation compressors—a difference that translates to substantial operational cost reductions over the equipment lifecycle. Even greater savings are possible when these compressors are combined with intelligent control systems that optimize performance across multiple units.

Modular and Scalable Systems

Modular compressor systems allow pharmaceutical manufacturers to match compressed air capacity to production demand with greater precision. Instead of investing in a single large compressor, facilities can deploy multiple smaller units operating in parallel, activating or deactivating units based on real-time demand.

This approach offers several compelling advantages:

- Improved part-load efficiency compared to oversized single units

- Enhanced reliability through built-in redundancy

- Simplified capacity expansion as production volumes grow

- Reduced upfront capital investment by matching immediate needs while allowing for future growth

- Easier maintenance scheduling with minimal production impact

Integration with Digital Manufacturing Systems

As pharmaceutical manufacturers increasingly adopt Industry 4.0 principles, compressed air systems are becoming more tightly integrated with overall facility management systems. This connectivity enables:

- Coordinated control with other utility systems for optimized resource utilization

- Advanced energy management and load balancing across the entire facility

- Automated data collection for regulatory compliance documentation

- Remote monitoring and control capabilities, facilitating expert support regardless of location

- Integration with manufacturing execution systems (MES) for comprehensive process optimization

Implementation Best Practices

Successfully implementing an oil-free compressed air system requires careful planning to ensure compliance, reliability, and optimal performance. These best practices emerge from extensive industry experience implementing hygienic air compression solutions in pharmaceutical environments:

System Design Considerations

- Air Treatment Integration: Design complete air treatment systems (dryers, filters, separators) as integral components of the compressed air system, not as afterthoughts. This ensures consistent delivery of required air quality throughout all production areas.

- Pipe Sizing and Layout: Properly sized and sloped piping minimizes pressure drops and prevents moisture accumulation—both critical factors for maintaining air quality and system efficiency in pharmaceutical applications.

- Condensate Management: Implement effective condensate drainage with appropriate treatment systems to prevent environmental contamination and meet pharmaceutical wastewater regulations, particularly for water-injected compressors.

- Accessibility for Maintenance: Design compressor room layouts with adequate space for all maintenance activities, including filter changes, inspections, and component replacement, while maintaining proper segregation from production areas.

Installation and Commissioning

- Qualified Installers: Utilize experienced, factory-trained technicians for proper system setup and alignment to ensure optimal performance and prevent premature failure.

- Comprehensive Testing: Conduct thorough performance testing before production use, including ISO 8573 air quality testing across all operating conditions and load levels.

- Validation Documentation: Develop complete validation documentation with installation qualifications (IQ), operational qualifications (OQ), and performance qualifications (PQ) as required by GMP regulations and internal quality standards.

- Operator Training: Ensure operators and maintenance personnel receive comprehensive training on system operation, maintenance procedures, and quality monitoring to maintain system integrity and performance.

Ongoing Monitoring and Maintenance

- Regular Air Quality Testing: Implement scheduled testing protocols to verify ISO 8573-1 compliance, with more frequent testing for critical applications and after any maintenance activities.

- Preventive Maintenance Program: Establish a comprehensive preventive maintenance schedule based on manufacturer recommendations and operating experience, with clear documentation of all activities.

- Performance Monitoring: Continuously track key performance indicators like energy consumption, pressure stability, and maintenance frequency to identify optimization opportunities and emerging issues.

- Change Control Procedures: Implement formal change control processes for all system modifications, including proper documentation and revalidation when necessary to maintain compliance with pharmaceutical compression standards.

Conclusion: Making the Right Choice for Your Pharmaceutical Facility

Selecting the optimal oil-free compressor technology requires balancing air quality requirements, energy efficiency, reliability, and total cost of ownership. Scroll compressors generally offer advantages in air purity, partial load efficiency, and lower maintenance requirements for small to medium capacity applications. In contrast, screw compressors may be better suited for large-scale operations with continuous high air demand and stable production schedules.

The pharmaceutical industry's increasing focus on contamination control, energy efficiency, and digitalization makes compressed air systems more critical than ever to manufacturing operations. Manufacturers must approach compressor selection as a strategic decision with far-reaching implications for daily operations, long-term competitiveness, and regulatory compliance.

Revos' innovations in oil-free scroll compressor technology have effectively addressed many traditional limitations, offering pharmaceutical manufacturers Class O air purity with excellent energy efficiency and reliability. Following the selection framework outlined in this guide will help decision-makers make informed choices that support quality objectives while optimizing operational performance and costs.

Ultimately, the choice between scroll and screw technologies should emerge from a thorough analysis of application requirements, operational patterns, and business goals. By prioritizing air quality, reliability, and efficiency, pharmaceutical manufacturers can implement compressed air systems that support regulatory compliance, enhance product quality, and contribute to overall operational excellence.

As with any critical manufacturing decision, involving stakeholders from quality, production, engineering, and finance departments ensures a comprehensive evaluation that aligns with