In healthcare facilities where patient safety and operational reliability are paramount, selecting the appropriate medical grade air compressor impacts multiple facets of clinical operations. Drawing from extensive experience implementing compressed air solutions across healthcare, pharmaceutical, and semiconductor sectors, I've witnessed firsthand how strategic equipment selection enhances efficiency while ensuring compliance with stringent regulatory standards.

The global medical air compressor market is experiencing robust growth, projected to reach $1.5 billion by 2025. This expansion reflects the increasing demand for advanced healthcare infrastructure and the rising adoption of minimally invasive procedures. These systems serve as vital components in modern healthcare—powering life-support equipment, enabling precision medical device operation, and supporting numerous diagnostic and therapeutic applications.

Understanding Medical Grade Air Compressor Requirements

Medical grade air compressors represent specialized equipment engineered to deliver continuous supplies of clean, dry, contamination-free compressed air for both direct and indirect patient applications. Unlike their industrial counterparts, these systems must adhere to rigorous standards designed to prevent the introduction of harmful contaminants into clinical environments.

ISO 8573-1 defines the core requirements for medical air compressors, establishing air quality classes based on allowable levels of particulate matter, water vapor, and oil contamination. For critical medical applications, Class O certification—indicating complete absence of oil contamination—has become the industry benchmark and represents the highest level of air purity available. This distinction carries significant importance, as even minute oil particles can compromise sterile environments and endanger patient safety.

Healthcare facilities must also navigate complex regulations such as NFPA 99 standards in the United States. These comprehensive guidelines address the design, installation, and maintenance of medical gas systems (including compressed air) with specific specifications for redundancy, alarm systems, and maintenance protocols to ensure uninterrupted supply. Any interruption in compressed air delivery can directly impact patient care and clinical outcomes.

Beyond regulatory compliance, facilities must carefully consider their specific clinical applications. Anesthesia delivery systems, for instance, have distinct flow rate requirements compared to respiratory therapy equipment or surgical tools. A thorough understanding of these application-specific needs is critical for determining the appropriate compressor capacity and configuration.

Key Technical Considerations for Selection

When evaluating medical grade air compressors, several technical factors demand careful consideration to ensure optimal performance and regulatory compliance.

Capacity requirements represent a primary consideration. The compressor must deliver sufficient airflow during peak demand periods without compromising pressure stability. Facilities should conduct a comprehensive analysis of all compressed air-consuming devices to determine both baseline and peak consumption patterns.

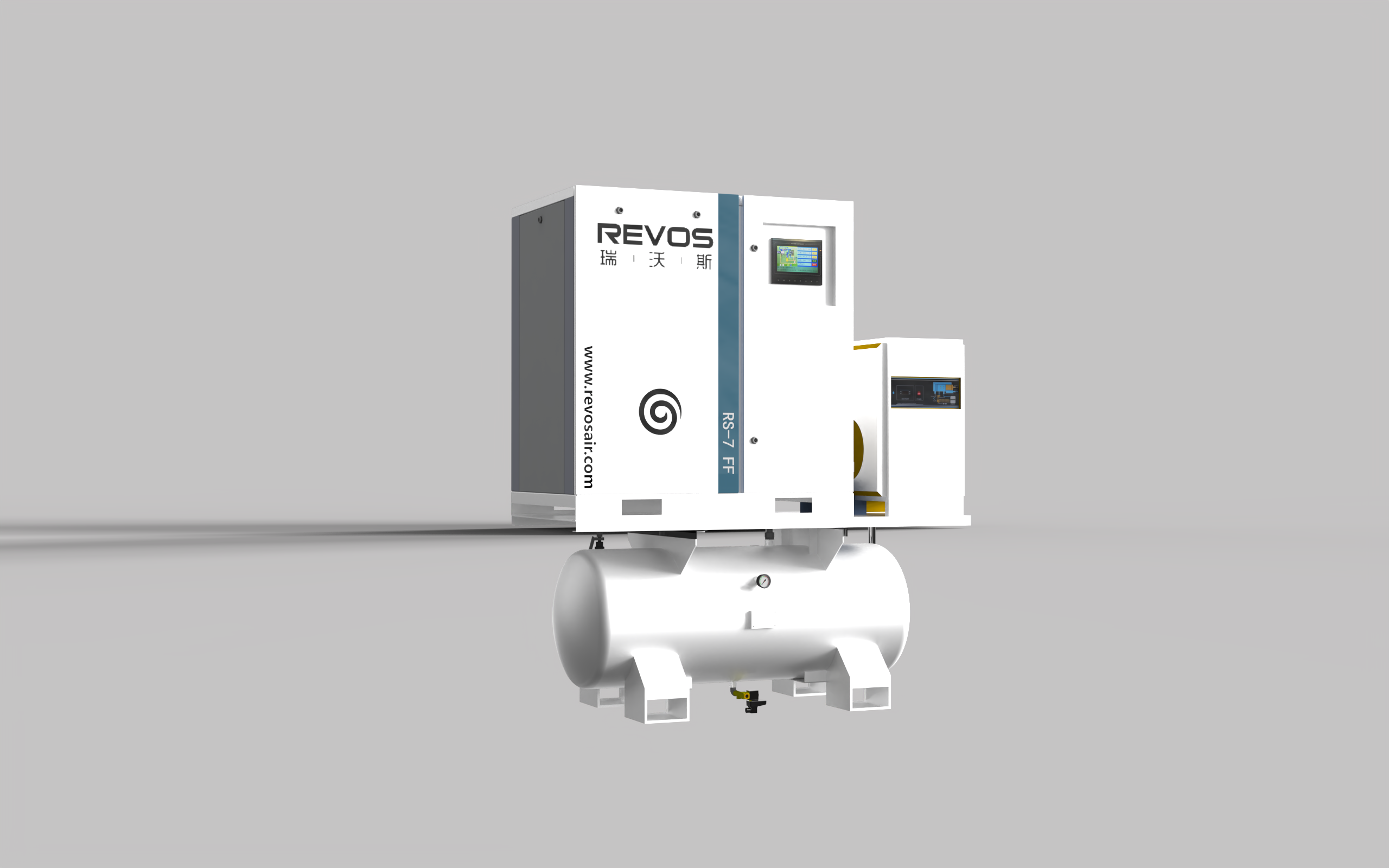

Oil-free technology has emerged as the gold standard in medical applications, eliminating oil contamination risks that could compromise patient safety and damage sensitive equipment. Within the category of oil-free compressors, facilities must choose between different technologies:

- Scroll compressors, which offer quieter operation and fewer moving parts, making them ideal for noise-sensitive environments

- Rotary screw compressors, which typically provide higher flow rates and greater durability for continuous-duty applications

Energy efficiency has become increasingly critical in compressor selection, driven by both cost containment initiatives and sustainability goals. Variable speed drive (VSD) technology adjusts motor speed based on demand, delivering significant energy savings compared to fixed-speed models—especially in facilities with variable air demand. Industry data indicates that VSD compressors can reduce energy consumption by 30% or more versus traditional fixed-speed units, resulting in substantial long-term savings.

System configuration plays a vital role in ensuring reliable operation:

- Redundancy features such as dual compressors or backup systems prevent service interruptions during maintenance or equipment failures

- High-efficiency dryers and multi-stage filtration systems maintain air quality standards and protect downstream equipment from moisture and particulate contamination

Noise levels represent a particular concern in healthcare environments where patient comfort and staff concentration are priorities. Installations should incorporate sound attenuation measures, and equipment selection should prioritize units specifically designed for low-noise operation—typically below 70 decibels for occupied areas.

Industry-Specific Applications and Requirements

While healthcare facilities have unique compressed air needs, medical grade air compressors serve other critical sectors where air quality and reliability are equally important.

Pharmaceutical Industry Applications

The pharmaceutical industry relies heavily on compressed air for processes ranging from tablet coating to sterile packaging, requiring compliance with both ISO 8573-1 standards and Good Manufacturing Practices (GMP). In pharmaceutical manufacturing, compressed air frequently contacts products or ingredients directly, making oil-free operation and rigorous filtration essential. Pharmaceutical compression standards typically specify ISO 8573-1 Class 1 standards for particulate matter and moisture—the highest air purity level available. These applications also often require comprehensive documentation and validation of the entire compressed air system to ensure regulatory compliance.

Food Industry Applications

The food and beverage industry represents another important application area where air quality directly impacts product safety and regulatory compliance. Food industry air compressors are used for bottle cleaning, product conveying, and packaging, requiring compliance with standards such as FDA 21 CFR Part 173.300 (addressing indirect food additives including compressed air). Food processing applications demand compressors that prevent contamination from oil, water, and particulates, with many facilities specifying ISO 8573-1 Class 2 or better air quality standards. Stainless steel construction and sanitary design features (smooth surfaces, minimal crevices) help prevent bacterial growth and facilitate cleaning—important considerations in hygiene-critical environments that require hygienic air compression solutions.

Semiconductor Industry Applications

The semiconductor industry has perhaps the most demanding compressed air requirements, often exceeding even healthcare standards. Semiconductor clean air solutions must deliver ultra-clean, dry air to prevent contamination of sensitive electronic components during fabrication. Cleanroom environments typically require ISO 8573-1 Class 1 air quality with additional specifications for molecular contamination control. These specialized systems must remove particulate matter, moisture, hydrocarbons, and other volatile organic compounds that could compromise wafer integrity. Advanced purification technologies like activated carbon adsorption and membrane dryers are employed to achieve the ultra-high purity levels needed for advanced semiconductor manufacturing processes.

Supplier Evaluation and Selection Criteria

Selecting a reputable supplier is a critical decision in acquiring medical grade air compressors, as equipment reliability directly impacts patient care and operational efficiency.

Compliance with industry standards forms the foundation of supplier evaluation. Prospective suppliers should demonstrate a clear understanding of and commitment to relevant standards: ISO 8573-1 for air quality, ISO 13485 for medical device manufacturing, and NFPA 99 for healthcare facilities. They should provide comprehensive documentation of certification and compliance, including third-party testing results verifying air quality performance.

Technical expertise and healthcare application experience are equally important considerations. Suppliers with proven track records in medical environments better understand the unique challenges and requirements of these facilities. Facilities should inquire about experience with similar healthcare installations and request references from comparable institutions.

Service and support capabilities ensure long-term reliability and performance. Suppliers should offer comprehensive maintenance programs specifically tailored to healthcare environments, including emergency service response, preventive maintenance schedules, and calibration services. The availability of local service technicians and spare parts inventory can significantly reduce downtime during equipment issues.

Equipment reliability and performance data should be thoroughly reviewed, including mean time between failures (MTBF) statistics and performance curves under various operating conditions. Suppliers should be transparent about performance limitations and provide realistic expectations regarding energy consumption, maintenance requirements, and service life.

Financial stability and long-term viability are often overlooked but critical factors. Healthcare facilities make significant investments in compressed air systems, and partnering with a financially unstable supplier could jeopardize future support and replacement parts availability. Reviewing financial statements, industry ratings, and market position helps assess supplier stability.

Finally, total cost of ownership (TCO)—not just initial purchase price—should guide selection. TCO includes energy consumption, maintenance costs, service contracts, and expected lifecycle to provide a more accurate picture of long-term value. A slightly higher initial investment in a more efficient, reliable system often yields significant savings over the equipment's operational life.

Maintenance and Compliance Best Practices

Establishing a robust maintenance program ensures the reliability, performance, and compliance of medical grade air compressor systems in healthcare environments. A well-designed maintenance strategy prevents unexpected downtime while ensuring ongoing regulatory compliance and air quality standards.

Preventive maintenance schedules should be based on manufacturer recommendations, regulatory requirements, and operational experience. These schedules should include regular inspections of all system components: compressors, dryers, filters, and distribution piping. Key maintenance activities include filter replacement, lubrication (for applicable components), condensate drain inspection, and pressure testing.

Documentation is critical in regulated healthcare environments. Facilities must maintain detailed records of all maintenance activities: dates, performed work, replacement parts, and test results. This documentation serves as compliance evidence during regulatory inspections and helps identify trends or recurring issues that may indicate underlying problems.

Air quality monitoring should be conducted regularly to verify continued compliance with ISO 8573-1 and other requirements. This includes both particulate matter and moisture testing, with more frequent testing recommended for critical care applications. Some facilities implement continuous monitoring systems that provide real-time data and alerts for immediate response to quality deviations.

Staff training represents another essential component. Operators and maintenance personnel should receive comprehensive training on system operation, maintenance procedures, and troubleshooting protocols. This training should be documented and updated regularly to keep staff current on best practices and regulatory requirements.

Emergency preparedness planning minimizes disruptions during system failures. Facilities should develop contingency plans with backup systems, alternative air sources, and response procedures for various failure scenarios. These plans should be regularly tested through drills to ensure staff familiarity and effectiveness.

Periodic system audits evaluate the overall effectiveness of the compressed air system and maintenance program. These audits assess compliance, performance, energy efficiency, and reliability to identify areas for improvement. External experts may be engaged for objective evaluation and optimization recommendations.

Future Trends and Technological Advancements

The medical grade air compressor industry continues to evolve, driven by technological advancements, changing regulations, and increasing focus on energy efficiency and sustainability. Healthcare facilities planning new installations or upgrades should consider these emerging trends to ensure their systems remain state-of-the-art and meet future needs.

Smart technology integration is transforming compressed air systems through Internet of Things (IoT) connectivity and advanced sensors that enable real-time performance monitoring. This technology provides valuable data on energy consumption, maintenance needs, and air quality. Predictive analytics algorithms analyze this data to identify potential issues before failures occur, enabling proactive maintenance and minimizing downtime.

Energy efficiency remains a major focus, with new technologies reducing environmental impact and operating costs. Variable speed drives (adjusting motor speed to match demand) are becoming standard features on many medical grade compressors, offering significant energy savings over fixed-speed models. Heat recovery systems are also gaining popularity, capturing waste heat from compressors for facility heating or water heating applications.

More compact, lightweight compressors are expanding installation possibilities in space-constrained healthcare facilities. These smaller units maintain the same performance and air quality standards as larger models while offering greater placement flexibility—a particular benefit for retrofitting existing facilities with limited space.

Advancements in filtration and purification technologies enable compressed air systems to achieve higher purity levels with greater energy efficiency. New filter media and designs provide improved particle removal while reducing pressure drop and energy losses. Next-generation dryer technologies (membrane and adsorption dryers) offer enhanced moisture removal with lower energy consumption.

Sustainability considerations increasingly influence compressor design and operation. Manufacturers are developing systems with lower global warming potential (GWP) refrigerants and more environmentally friendly materials. The trend toward "net-zero" healthcare facilities drives demand for compressors that can be integrated with renewable energy systems like solar power to reduce carbon footprints.

Artificial intelligence (AI) and machine learning are beginning to transform compressed air system management. AI-powered control systems optimize operation based on historical usage patterns, weather conditions, and facility occupancy—further improving energy efficiency and reliability. These intelligent systems automatically adjust to changing demand patterns, ensuring optimal performance under varying conditions.

Implementation and Optimization Strategies

Successfully implementing a new medical grade air compressor system requires careful planning and execution to minimize disruption to healthcare operations while achieving optimal performance and compliance.

System design should begin with a comprehensive assessment of current and future compressed air requirements. This assessment considers existing equipment, planned expansions, new technologies, and potential clinical practice changes that may affect air demand. Load profiling—measuring air consumption patterns over time—provides valuable data for proper system sizing.

Installation planning requires close coordination between facility management, clinical staff, contractors, and suppliers. In healthcare environments, installation activities must be scheduled to minimize disruption to patient care, often requiring after-hours or weekend work. Contingency plans should ensure that critical care areas maintain compressed air supply during installation and commissioning.

Commissioning verifies that the system operates according to design specifications and regulatory requirements. This process includes thorough testing of all components: air quality testing, performance verification, and safety system checks. Commissioning documentation should be detailed and retained as part of the facility's compliance records.

Staff training should be conducted before system startup to ensure operators and maintenance personnel are familiar with the new equipment. Training covers normal operation, troubleshooting, emergency procedures, and maintenance requirements. Hands-on sessions with actual equipment build staff confidence and competence.

Performance monitoring should begin immediately after startup to establish baseline operating parameters and identify adjustment needs. This monitoring includes tracking energy consumption, air quality, pressure stability, and system reliability metrics. Data collected during this period helps optimize system settings for maximum efficiency and performance.

Ongoing optimization should be viewed as a continuous process rather than a one-time activity. Regular reviews of system performance data, maintenance records, and changing facility needs identify opportunities for improvement. These opportunities may include adjusting operating parameters, implementing additional controls, or upgrading components to enhance efficiency, reliability, or air quality.

By following these implementation and optimization strategies, healthcare facilities ensure their medical grade air compressor systems provide reliable, efficient service while maintaining the highest air quality and regulatory compliance standards. The result supports quality patient care while minimizing operational costs and environmental impact.