In the food processing industry, compressed air functions as an indispensable utility that touches nearly every production stage—from pneumatic conveying of ingredients to operating packaging machinery and agitating mixtures in tanks. As regulatory bodies tighten food safety standards and consumers demand greater transparency, requirements for compressed air systems have evolved dramatically. Based on years of industry experience working with food processors and regulatory compliance, this guide outlines essential features, technical specifications, and best practices for selecting and maintaining air compressors in food manufacturing environments, while drawing comparisons to related standards in pharmaceutical and semiconductor applications.

Regulatory Framework and Compliance Standards

The foundation of any food-grade compressed air system lies in understanding and adhering to stringent regulatory requirements. The global food industry operates within a complex framework of standards dictating air quality, system design, and maintenance protocols. ISO 8573-1:2010 remains the cornerstone standard, classifying contaminants into three categories: solid particles, water, and oil. For direct food contact applications, the highest classification—Class 0 for oil contamination—has become the de facto requirement, as even trace oil amounts can compromise product safety and lead to costly recalls.

Beyond ISO standards, food processors must navigate region-specific regulations that often align with pharmaceutical compression standards. In the United States, the FDA's 21 CFR Part 117 establishes current Good Manufacturing Practices (cGMP) explicitly including compressed air as a potential contamination source. The European Union's EC 178/2002 regulation similarly mandates hazard analysis and critical control point (HACCP) implementation, where compressed air systems often represent critical control points. Recent 2025 HACCP guideline updates have strengthened real-time monitoring requirements, forcing food processors to implement continuous measurement systems for compressed air quality parameters.

Industry-specific certifications further complicate compliance. BRCGS, SQF, and FSSC 22000 standards all include specific compressed air clauses, with SQF Edition 9 (released early 2025) introducing more rigorous documentation requirements for compressor maintenance and filter replacement schedules. These standards emphasize not just final air quality but the entire system design—from intake location to distribution piping—to prevent contamination throughout production, reflecting similar principles found in semiconductor clean air solutions.

Key Technical Specifications for Food Industry Air Compressors

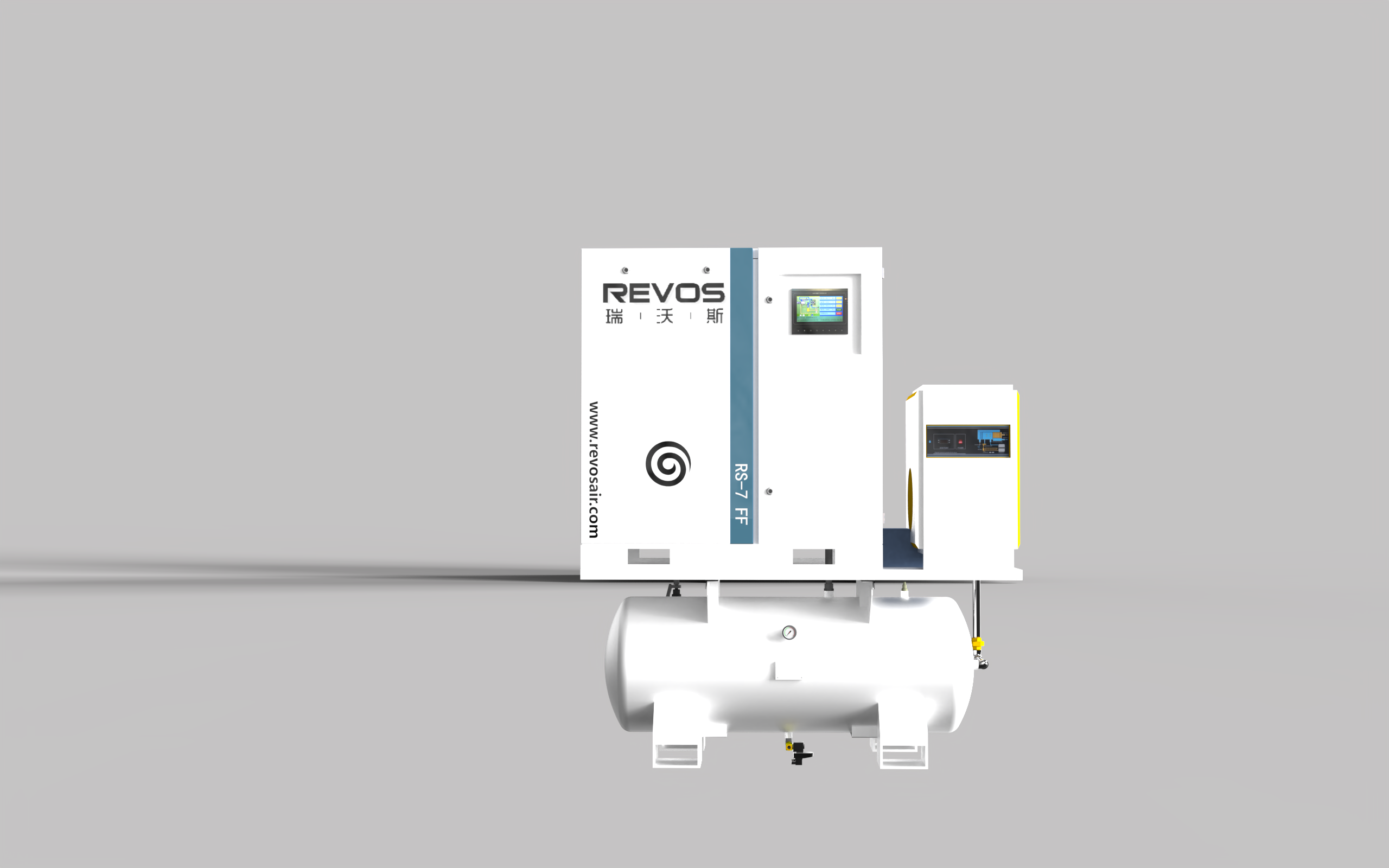

Selecting the right air compressor for food processing requires careful consideration of technical specifications balancing performance, hygiene, and efficiency. The primary distinction lies in compressor technology, with oil-free rotary screw compressors dominating the food industry due to their ability to deliver consistent air quality without lubricant carryover. These compressors use precision-machined rotors in a sealed chamber, eliminating oil lubrication in the compression chamber and preventing the most common compressed air contamination source.

Air quality specifications must align with ISO 8573-1 classes, with food processors typically requiring:

- Class 0 for oil content: Achieved through oil-free compression technology combined with high-efficiency coalescing filters (typically 0.01 micron rating)

- Class 2 for water vapor: Maintained through refrigerated or desiccant dryers to achieve pressure dew points of -40°C or lower

- Class 2 for solid particles: Utilizing multi-stage filtration systems including pre-filters, particulate filters, and activated carbon filters

Pressure and flow requirements vary significantly across food processing applications. Most pneumatic equipment operates at 6-8 bar(g), while specialized applications like high-pressure cleaning may require up to 10 bar(g). Flow rates are equally application-dependent—a typical dairy processing facility needs 50-150 m³/min, while a bakery might operate efficiently with 10-30 m³/min. Conducting a thorough air audit to match compressor capacity with actual demand is critical, as oversized systems waste energy and increase maintenance costs.

Material selection represents another critical consideration often overlooked in standard industrial compressors. Food-grade systems require stainless steel (316L) air receivers and contact parts to prevent corrosion and bacterial growth. Piping systems should feature smooth internal surfaces with minimal elbows and drains positioned to eliminate water pooling. The 2025 trend toward hygienic design has introduced innovations like quick-disconnect fittings for easy cleaning and sloped piping to ensure complete drainage, further reducing contamination risks—similar to design principles used in medical grade air compressors.

Technological Trends Shaping Food Industry Compressors

The food processing industry leads in adopting advanced compressed air technologies that enhance both safety and operational efficiency. The most significant trend driving 2025 market growth is integration of smart monitoring systems providing real-time visibility into compressor performance and air quality. These IoT-enabled solutions continuously measure key parameters like dew point, particle count, and oil carryover, alerting operators to potential issues before they impact production or product quality.

Energy efficiency has emerged as a primary concern for food processors facing rising utility costs and sustainability targets. Variable speed drive (VSD) compressors have become standard, adjusting motor speed to match actual air demand and reducing energy consumption by 20-35% compared to fixed-speed models. Regenerative thermal oxidizers (RTOs) for heat recovery are gaining traction, capturing waste heat from compression to preheat water or production spaces. A recent case study from a major candy manufacturer documented 21% energy savings within five months of implementing a smart compressed air system with heat recovery, resulting in a projected 14-month payback period.

Compression technology miniaturization has enabled decentralized air systems, where smaller compressors located closer to point-of-use reduce pressure drops and improve efficiency. This distributed approach also enhances redundancy, ensuring production continuity even if one compressor needs maintenance. For facilities with multiple production lines, this modular design allows precise capacity matching and simplifies expansion planning—principles that also apply to semiconductor clean air solutions.

Sustainability considerations drive innovation in compressor design, with manufacturers introducing models optimized for low global warming potential (GWP) refrigerants and recyclable materials. The 2025 introduction of magnetic bearing technology in oil-free compressors represents a significant advancement, eliminating mechanical contact points and reducing maintenance requirements while improving energy efficiency by an additional 5-8% compared to conventional designs.

Selection Criteria and System Design Considerations

Selecting the optimal compressed air system for a food processing facility involves systematic evaluation of both technical requirements and operational constraints. The process should begin with a comprehensive compressed air audit mapping current and future air demands across all production lines. This audit identifies peak usage periods, pressure requirements for each application, and potential contamination risk points.

When evaluating compressor suppliers, food processors should prioritize manufacturers with specific hygienic application experience. Key questions for potential suppliers include:

- What specific certifications do their compressors hold for food industry applications?

- Can they provide validation documentation for ISO 8573-1 Class 0 compliance?

- What is their approach to system integration with existing food safety management systems?

- How do they support regulatory compliance during audits?

System design extends beyond the compressor itself to encompass the entire air treatment train. A typical food-grade system includes:

- Intake filtration: Multi-stage filters removing atmospheric contaminants before compression

- Oil-free compressor: Rotary screw or scroll technology with Class 0 certification

- Aftercooler: Removes condensation generated during compression

- Refrigerated/desiccant dryer: Controls moisture content to specified dew point

- Filtration train: Sequential particulate, coalescing, and activated carbon filters

- Stainless steel receiver: With proper drainage and inspection ports

- Distribution system: Hygienic piping with minimal dead legs and proper slope

- Monitoring system: Continuous measurement of pressure, flow, dew point, and particle count

Compressor room location represents a critical design consideration often overlooked. Intake air should come from a clean, elevated location away from potential contaminants like exhaust vents, loading docks, or raw material storage areas. The room itself should feature positive pressure ventilation, washable surfaces, and easy maintenance access while remaining segregated from production areas to prevent cross-contamination—similar to requirements for medical grade air compressors in healthcare facilities.

Maintenance and Validation Best Practices

Maintaining compressed air quality in food processing requires a rigorous preventive maintenance program tailored to hygienic application demands. The foundation of this program is a comprehensive maintenance schedule addressing both the compressor unit and associated air treatment equipment. For oil-free compressors, critical maintenance tasks include daily checks of differential pressure across filters, weekly inspection of condensate drains, and monthly verification of dew point performance.

Filter replacement represents a particularly critical maintenance activity, with intervals determined by differential pressure monitoring rather than fixed time periods. Particulate filters typically require replacement when pressure drop exceeds 0.2 bar, while coalescing filters for oil removal should be changed when differential pressure reaches 0.3 bar or every 6 months, whichever comes first. Activated carbon filters for odor and hydrocarbon removal generally have shorter service lives, often requiring replacement every 3 months in continuous operation.

Validation and documentation form the cornerstone of regulatory compliance for food industry compressed air systems. Facilities should implement a regular testing schedule including:

- Monthly particle count testing according to ISO 8573-4 methodology

- Quarterly oil vapor analysis using photoionization detection (PID)

- Semi-annual microbial testing via impaction or impingement methods

- Annual comprehensive system audits including leak detection and pressure testing

Continuous monitoring technology has revolutionized maintenance practices in 2025. Wireless sensors throughout the compressed air system provide real-time data on pressure, flow, temperature, dew point, and filter status. This data enables predictive maintenance, identifying potential issues before they impact air quality or system performance. Integration with manufacturing execution systems (MES) allows automated alerts and documentation, streamlining compliance reporting during regulatory audits.

Staff training remains a critical component of any maintenance program. Operators should receive specialized training on the unique requirements of hygienic compressed air systems, including proper procedures for filter replacement, condensate handling, and emergency shutdowns. Many food processors have implemented certification programs for maintenance technicians responsible for compressed air systems, ensuring consistent application of best practices across shifts.

Case Studies and Industry Applications

Practical application of hygienic compressed air systems varies widely across food processing sectors, with each industry segment presenting unique challenges and solutions. The dairy industry exemplifies the most stringent requirements, using compressed air in direct contact applications like milk agitation, cheese pressing, and yogurt fermentation. A leading dairy producer recently upgraded to a complete oil-free compressed air system, resulting in 37% fewer microbial contamination incidents and eliminating all oil-related quality issues, while achieving 28% energy cost reduction through VSD technology and heat recovery.

Bakery operations demonstrate decentralized compressed air system benefits, with multiple small compressors strategically placed near production lines. This approach reduced pressure losses by 40% and eliminated extensive piping networks that could harbor contaminants. Smart monitoring implementation allowed the facility to identify and repair leaks totaling nearly 15% of total air production, further improving efficiency and reducing energy consumption.

Meat and poultry processing facilities face unique challenges due to wet environments and strict sanitation requirements. Stainless steel compressor packages with washdown-rated enclosures have become standard, allowing equipment to withstand daily cleaning protocols. One poultry processor documented 50% lower maintenance costs after upgrading to corrosion-resistant equipment specifically designed for wet environments, while also improving compliance with USDA sanitation standards.

Beverage production facilities use compressed air for bottle cleaning, filling, and capping operations, requiring both high purity and consistent pressure. A major brewery implemented a combined system of oil-free compressors and nitrogen generators, reducing their carbon footprint by 18% while improving product shelf life through better oxygen control. Integrating air quality data with their quality management system enabled real-time product release, reducing holding times by 40%.

These case studies show that while core hygienic compressed air principles apply across the food industry, successful implementation requires customization to specific production environments and regulatory requirements. The most successful projects typically involve close collaboration between compressor manufacturers, system integrators, and food safety professionals from initial design through commissioning and validation.

Future Outlook and Emerging Technologies

The food processing industry continues evolving in response to changing consumer demands, regulatory requirements, and technological advancements—all shaping the future of compressed air systems. Looking ahead to 2025 and beyond, several emerging trends will transform compressed air technology in food applications.

Artificial intelligence (AI) and machine learning integration represents the most significant advancement on the horizon. Predictive analytics platforms will become increasingly sophisticated, not just identifying maintenance needs but optimizing compressor performance in real-time based on production schedules, ambient conditions, and energy pricing. Early adopters already report 5-10% additional energy savings through AI-driven optimization, with further improvements expected as algorithms refine.

Convergence of compressed air technology with industrial internet of things (IIoT) platforms will enable unprecedented visibility into system performance. Cloud-based monitoring systems provide remote access to real-time and historical data on air quality, energy consumption, and maintenance activities, facilitating benchmarking across multiple facilities and simplifying compliance reporting. This connectivity also enables remote diagnostics, reducing downtime and improving service response times—similar to monitoring systems used in pharmaceutical compression standards.

Material science innovations will continue enhancing compressor performance and reliability. Advanced ceramic coatings for compression components promise reduced friction and improved efficiency, while novel filter media will extend service lives and improve contaminant removal. More efficient heat recovery systems will further improve compressed air system sustainability profiles, potentially approaching energy-neutral operation in some applications.

Regulatory evolution will continue driving technology development, with anticipated ISO 8573 standard updates incorporating more stringent microbiological contamination requirements. This may lead to wider adoption of ultraviolet or ozone-based air treatment technologies for microbial control, particularly in high-risk applications like ready-to-eat foods.

As the food industry faces increasing pressure to reduce environmental footprint, compressed air systems will play a key role in sustainability initiatives. Small-scale, on-site nitrogen generation from compressed air already reduces reliance on bottled gases, while further efficiency improvements will enable compressed air to contribute to carbon neutrality goals. Eventual integration of renewable energy sources with variable-speed compressor systems represents the ultimate sustainability target, though significant technical challenges remain.

In summary, selecting and managing compressed air systems in food processing facilities requires a holistic approach balancing technical performance, regulatory compliance, and operational efficiency. By staying informed of technological advancements and best practices, food processors can ensure their compressed air systems support both food safety objectives and business goals in an increasingly competitive industry landscape. The most successful operations view compressed air not merely as a utility, but as a strategic asset contributing to product quality, operational efficiency, and regulatory compliance—whether implementing food industry air compressors, medical grade air compressors, or semiconductor clean air solutions.