As modern manufacturing facilities prioritize sustainability and operational excellence, understanding the latest advancements in oil-free air compressor technology has become essential for industrial decision-makers. This authoritative guide examines current efficiency standards, compares leading compression technologies, and provides actionable selection strategies for optimizing compressed air systems in accordance with 2025 regulatory requirements and industry best practices.

The Regulatory Framework Shaping Compressor Efficiency

Global energy conservation initiatives have driven significant updates to compressor efficiency regulations, creating a more structured compliance landscape for industrial operators. The 2025 implementation of revised standards represents a critical inflection point for equipment specifications and procurement decisions.

In January 2025, the U.S. Department of Energy (DOE) introduced enhanced air compressor regulations establishing minimum efficiency thresholds across various categories, including specific mandates for oil-free models. These standards project energy savings of 0.16 quadrillion British thermal units over three decades, contributing to a 0.6% improvement in overall industrial energy efficiency metrics.

Across the Atlantic, EU Directive 2023/1791 mandates stricter energy efficiency requirements for member states, with transposition required by October 2025. Many European countries are expected to exceed these baseline requirements, aligning with ISO 50001 energy management systems to create a comprehensive regulatory framework. For oil-free compressors, these regulations emphasize isentropic efficiency measurements, with the DOE establishing a 53% minimum isentropic efficiency benchmark for certain categories—a specification influencing equipment design and selection in global markets.

Core Technologies in Oil-Free Compression

The foundation of energy-efficient compressed air systems lies in the compression technologies themselves. Three distinct approaches have emerged as industry standards, each offering unique efficiency characteristics and operational profiles tailored to specific industrial applications.

Scroll Type Air Compressors

Scroll compressors operate on a positive displacement principle utilizing two intermeshing spiral elements—one stationary and one orbiting—to compress air. This innovative design eliminates valve requirements and creates a continuous compression process that minimizes energy losses. The unique discharge port configuration optimizes internal compression ratios, enhancing overall efficiency.

Significant technological advancements in 2022 revolutionized scroll tooth design, particularly in developing oil-free variants capable of meeting stringent ISO 8573-1 Class O certification standards for air purity. These engineering breakthroughs have established scroll type air compressors as viable solutions for applications demanding both efficiency and contamination-free air, including pharmaceutical manufacturing and electronics production where air quality directly impacts product integrity.

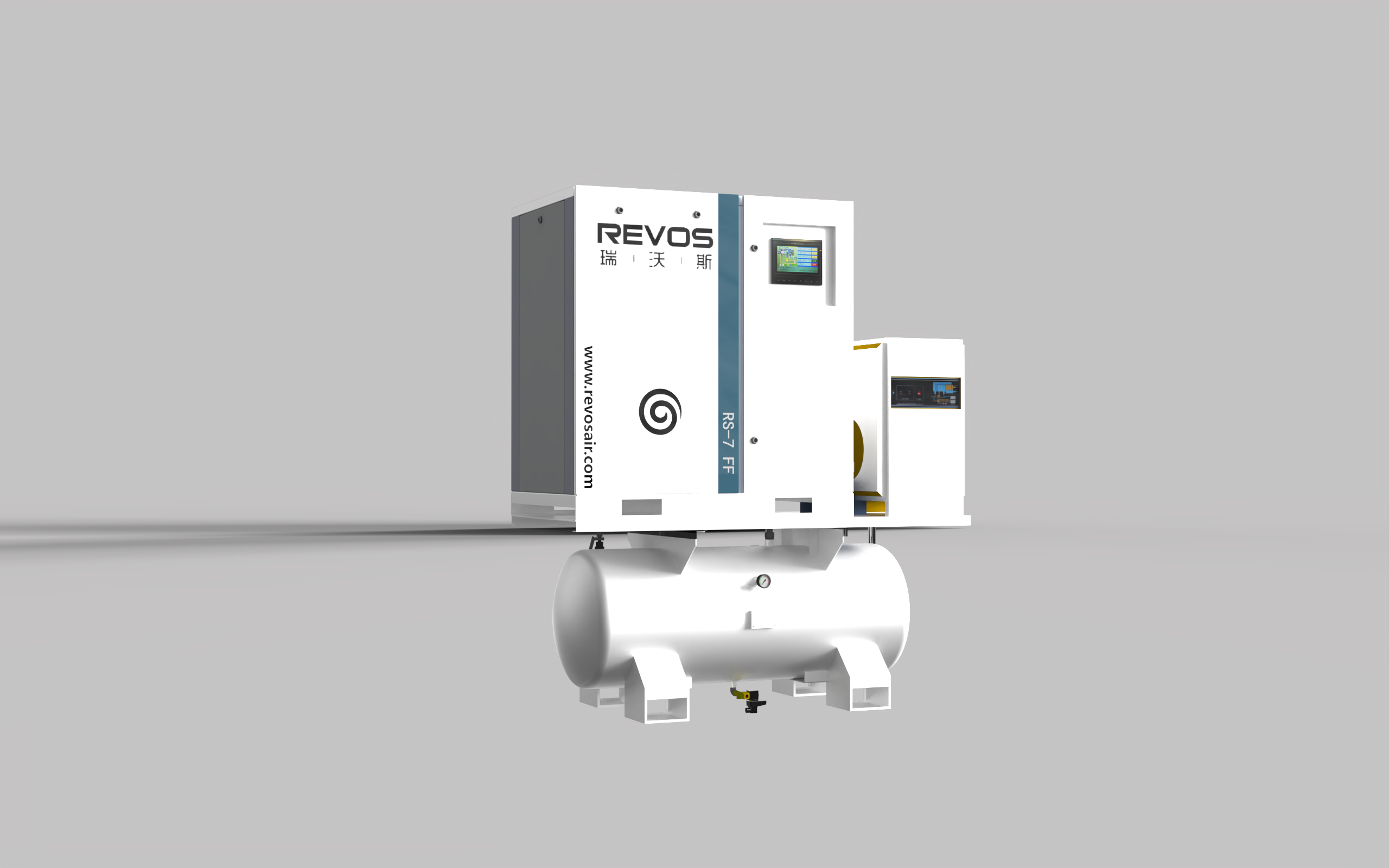

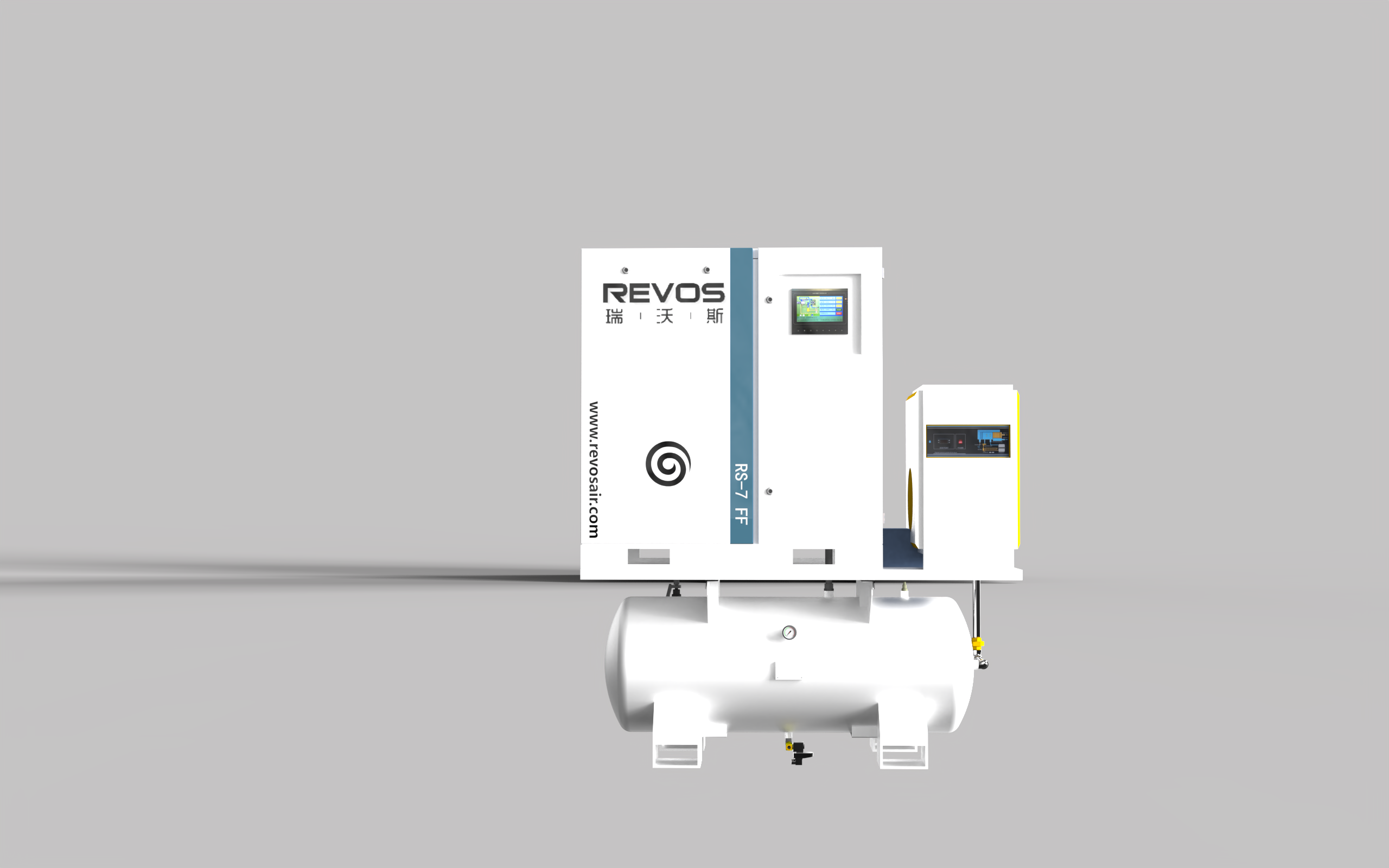

Screw Compressor Technology

Screw compressor technology employs rotating helical rotors to trap and compress air, delivering robust performance for continuous-duty industrial applications. While traditionally associated with oil-flooded designs, contemporary oil-free screw compressors utilize specialized air ends and advanced materials to achieve Class O certification. These compressors excel in high-volume applications where consistent pressure delivery is critical to production processes.

Recent innovations in screw compressor technology have focused on improving isentropic efficiency and reducing no-load power consumption. Premium efficiency IE3 motors have become standard, while variable speed drives (VSDs) allow these compressors to adapt to fluctuating demand profiles—an essential feature for energy optimization in dynamic manufacturing environments.

Rotary Tooth Compression Mechanism

The rotary tooth compression mechanism represents a significant technological advancement in oil-free compression, integrating elements of both scroll and screw designs. This hybrid approach features precision-engineered interlocking teeth that create multiple compression chambers, enabling higher flow rates with reduced energy input. The technology has gained traction in applications requiring both high efficiency and ultra-pure air, with certain manufacturers achieving Class O certification while demonstrating substantial energy savings compared to traditional designs.

The rotary tooth compression mechanism's unique architecture minimizes internal leakage and pressure losses, delivering efficiency gains of up to 15% in specific operating ranges. This technology particularly benefits applications with variable demand profiles, combining the best efficiency characteristics of both scroll and screw technologies across a broader operating spectrum.

Comparative Analysis: Efficiency Profiles of Compression Technologies

The selection between scroll, screw, and rotary tooth technologies depends on application-specific requirements, with efficiency performance varying significantly under different operating conditions. Understanding these performance characteristics is critical for optimizing total cost of ownership.

Under partial load conditions—typically defined as operating at less than 70% capacity—scroll type air compressors demonstrate superior efficiency characteristics. Independent testing confirms that scroll technology can achieve a 15-20% higher Integrated Part Load Value (IPLV) compared to screw compressors in variable demand scenarios. This advantage stems from the scroll design's ability to modulate output more precisely without significant efficiency penalties during turndown operation.

For continuous full-load operation, screw compressor technology often maintains a slight efficiency edge, particularly in larger capacity ranges (above 75 kW). However, when considering the typical duty cycles of most industrial applications—where variable demand is common—the overall efficiency advantage often shifts to scroll technology. Case studies tracking 4,000 hours of annual operation consistently show 12-18% energy savings with scroll compressors compared to conventional screw models, with equipment price differentials typically offset within 3-5 years through reduced energy consumption.

The rotary tooth compression mechanism offers a compelling middle ground, delivering efficiency advantages across both partial and full load conditions in certain capacity ranges. This technology particularly benefits facilities with highly variable demand profiles, providing efficiency benefits of scroll technology during partial load operation while approaching the full-load efficiency of screw compressors.

Essential Efficiency Metrics and Performance Standards

When evaluating oil-free compressor efficiency, industrial buyers must consider several critical metrics that directly impact energy consumption and operational costs. These performance indicators, often specified in manufacturer datasheets and third-party certification reports, provide a standardized basis for comparison.

Isentropic efficiency measures the ratio of theoretical work required to compress air versus actual energy input, serving as the fundamental efficiency metric for compressors. The 2025 DOE standards establish minimum isentropic efficiency levels across various compressor types and sizes, with oil-free models generally subject to higher thresholds than their oil-flooded counterparts.

Specific power consumption, expressed in kilowatts per cubic meter per minute (kW/m³/min), represents another essential benchmark. This metric enables direct comparison of energy efficiency between different compressor models at rated operating conditions. For oil-free scroll compressors in the 15-37 kW range, typical specific power consumption ranges from 5.5 to 7.0 kW/m³/min. Screw compressors in the same category generally fall within the 6.0 to 7.5 kW/m³/min range under full load conditions, though these values vary significantly by manufacturer and specific model design.

Airflow delivery stability significantly impacts system performance but is often overlooked in efficiency evaluations. Compressors that maintain consistent pressure and flow rates despite demand fluctuations minimize energy waste associated with pressure drops or over-compression. Advanced control systems and variable speed drives enhance this stability while contributing to overall efficiency, particularly in facilities with variable production schedules.

Technological Innovations Driving Efficiency Improvements

The compressed air industry has witnessed remarkable technological advancements that are redefining efficiency standards for oil-free compressors. These innovations address not only the compression process itself but also the intelligent management of compressed air systems as integrated components of industrial energy ecosystems.

Smart Monitoring and IoT Integration

IoT-enabled monitoring systems have emerged as transformative tools for optimizing compressor efficiency. These systems utilize advanced sensors to collect real-time data on pressure, flow, temperature, and energy consumption, providing operators with actionable insights to reduce waste. Case studies from 2025 demonstrate that manufacturing facilities implementing IoT-based compressed air monitoring achieve average energy savings of 15-20%, with some installations reporting up to 25% reduction in compressor-related energy costs through continuous optimization.

Predictive maintenance capabilities further contribute to efficiency by minimizing unplanned downtime and optimizing maintenance schedules. Machine learning algorithms analyze operational data to identify potential issues before they impact performance, ensuring compressors operate at peak efficiency throughout their service life while reducing maintenance costs.

Variable Speed Drives and Advanced Controls

Variable speed drive (VSD) technology has become increasingly sophisticated, allowing compressors to precisely match output to demand. Modern VSD systems can modulate motor speed across a wide range, eliminating energy penalties associated with traditional load/unload cycling. When combined with advanced control algorithms that coordinate multiple compressors in a system, these drives enable optimal efficiency across the entire operating range, particularly benefiting facilities with variable production schedules.

Material Science and Lubrication Innovations

Advancements in materials technology have significantly improved oil-free compressor efficiency. Ceramic coatings and advanced polymers reduce friction between moving parts, while precision manufacturing techniques ensure tighter tolerances that minimize internal leakage. For oil-free screw compressors, these material innovations have been particularly impactful, allowing for higher compression efficiencies without lubrication. Similarly, advanced composite materials have enabled more precise manufacturing of scroll elements, reducing clearance volumes and improving compression efficiency in scroll type air compressors.

Strategic Selection Criteria for Energy-Efficient Oil-Free Compressors

Selecting the optimal oil-free compressor requires systematic evaluation of application requirements, efficiency metrics, and total cost of ownership. Based on industry best practices and 2025 technology trends, industrial buyers should consider the following key factors during the decision process:

Air Quality Requirements

The first consideration in compressor selection is the required air quality standard defined by ISO 8573-1. For pharmaceutical, food processing, and electronics manufacturing applications, Class O certification—indicating complete absence of oil contamination—is typically mandatory. Leading manufacturers offer compressors certified to this standard across all three technologies, providing the highest level of air purity for critical processes.

Demand Profile Analysis

Thorough analysis of the compressed air demand profile is essential for optimizing efficiency. Facilities with consistent, high-volume demand may benefit from different technologies than those with variable or intermittent usage patterns. Data logging of pressure, flow, and usage patterns over a representative period (typically 2-4 weeks) provides the foundation for informed decision-making, revealing whether the application would best be served by scroll, screw, or rotary tooth compression mechanism technology.

Efficiency at Actual Operating Conditions

Manufacturer-provided efficiency data often reflects ideal operating conditions that may not match real-world applications. Industrial buyers should request performance curves across the entire operating range and verify efficiency metrics at the specific pressure and flow requirements of their application. Including system pressure drops and auxiliary equipment power consumption in efficiency calculations ensures a comprehensive assessment of true operating efficiency.

Total Cost of Ownership Analysis

While initial purchase price is a consideration, total cost of ownership—encompassing energy consumption, maintenance, and lifecycle costs—provides a more accurate basis for comparison. Tools such as the 5-year ROI calculator developed by industry organizations help quantify the long-term financial impact of efficiency differences between compressor models. Analysis typically reveals that higher-efficiency models, despite higher initial costs, yield significant savings over the equipment lifecycle.

Integration with Existing Systems

For retrofit applications, compatibility with existing compressed air infrastructure must be evaluated. Factors such as pressure ratings, flow capacity, and control system integration influence both efficiency and implementation costs. In some cases, upgrading ancillary equipment such as dryers, filters, and distribution piping may be necessary to fully realize the efficiency potential of new compressor technology, regardless of whether scroll, screw, or rotary tooth compression mechanism is selected.

Real-World Applications: Efficiency Improvements in Industrial Settings

Practical application of advanced oil-free compressor technology has yielded significant efficiency improvements across various industrial sectors. These case studies demonstrate tangible benefits of implementing modern, energy-efficient compressed air systems.

Pharmaceutical Manufacturing Facility Upgrade

A major pharmaceutical manufacturer replaced aging oil-free screw compressors with state-of-the-art scroll technology equipped with IoT monitoring systems. The upgrade resulted in 17% reduction in compressed air energy consumption, corresponding to annual savings of approximately 240,000 kWh. Implementing predictive maintenance capabilities also reduced unplanned downtime by 35% while ensuring compliance with strict ISO 8573-1 Class O air quality standards. The project demonstrated how scroll type air compressors could deliver superior efficiency in a facility with variable demand patterns.

Electronics Production Plant Optimization

An electronics manufacturing facility implemented a centralized compressed air system featuring variable speed drive oil-free screw compressors with advanced control algorithms. By matching compressor output precisely to production demand and integrating smart pressure and flow sensors throughout the distribution network, the facility achieved 22% improvement in specific energy consumption (kW/m³/min). The project qualified for utility rebates and achieved payback in 2.8 years, showcasing the efficiency potential of modern screw compressor technology when properly applied to high-volume applications.

Food Processing Energy Retrofit

A food processing plant replaced conventional lubricated compressors with oil-free rotary tooth technology as part of a comprehensive energy retrofit program. The new system included heat recovery for process heating applications, reducing overall site energy consumption by 9% while eliminating product contamination risks associated with oil carryover. Air quality improvements also contributed to enhanced product shelf life and reduced waste. This application demonstrated the unique benefits of the rotary tooth compression mechanism in facilities requiring both high efficiency and ultra-pure air.

Future Directions: Emerging Trends in Oil-Free Compressor Efficiency

Looking beyond 2025, several emerging trends are poised to further advance the efficiency of oil-free compressor technology. These developments reflect the ongoing convergence of energy conservation, digitalization, and sustainability in industrial equipment design.

Advanced Materials and Manufacturing

Continued innovation in materials science will enable further efficiency gains through reduced friction and improved heat management, including application of carbon fiber composites and advanced ceramics. Additive manufacturing techniques will facilitate more complex, optimized compressor geometries that maximize airflow and minimize energy losses across all technologies, including scroll type air compressors and screw compressor technology platforms.

Digital Twin Technology

Adoption of digital twin technology—virtual replicas of physical compressor systems—will enable more precise performance optimization and predictive maintenance. These digital models simulate various operating scenarios and identify efficiency bottlenecks, allowing operators to fine-tune system parameters for maximum energy savings regardless of the underlying compression technology.

Integration with Renewable Energy Sources

As industrial facilities increasingly incorporate renewable energy into their power mix, compressors will be optimized to operate in harmony with variable energy inputs. Solar-integrated compressor systems already emerging in 2025 demonstrate potential for direct integration with on-site renewable generation, further reducing carbon footprints and energy costs across all compression technologies.

Hydrogen-Compatible Compression

Growing industrial focus on hydrogen as an energy carrier drives development of oil-free compressors compatible with hydrogen service. These specialized compressors must handle the unique properties of hydrogen gas while maintaining efficiency standards established for traditional compressed air applications. The rotary tooth compression mechanism shows particular promise in this emerging application area, with its multiple compression chambers potentially better suited for hydrogen's characteristics compared to traditional designs.

Strategic Guidelines for Industrial Procurement Professionals

Selecting and implementing energy-efficient oil-free compressors requires a structured approach balancing technical requirements, regulatory compliance, and financial considerations. Based on industry best practices, these guidelines provide a framework for industrial buyers navigating the complex landscape of modern compressed air systems.

Conduct a Comprehensive System Audit

Before selecting new compressor equipment, perform a detailed audit of your existing compressed air system to identify inefficiencies, leaks, and optimization opportunities. This audit should include measurement of pressure drops, flow profiles, and energy consumption patterns while considering the entire system from generation to point of use. The audit results will help determine whether scroll, screw, or rotary tooth compression mechanism technology best suits your application.

Establish Clear Performance Specifications

Develop detailed performance specifications based on your specific application requirements. Include air quality standards, pressure and flow requirements, duty cycle, and efficiency targets. Reference relevant standards such as ISO 8573 for air quality and AHRI 540 for performance rating to ensure consistent comparison between manufacturers offering different compression technologies.

Evaluate Total Cost of Ownership

When comparing compressor options, consider not just initial purchase price but also energy consumption, maintenance, and lifecycle costs. Use a minimum 5-year time horizon for lifecycle cost analysis, incorporating factors such as utility rates, maintenance labor costs, and spare parts expenses. This comprehensive approach reveals the true value proposition of different technologies, whether evaluating scroll type air compressors, screw compressor technology, or rotary tooth compression mechanism options.

Consider Future Expansion and Flexibility

Anticipate future production changes and growth when selecting compressor capacity and configuration. Modular systems allowing for incremental expansion can help avoid over-investment in unused capacity while providing flexibility to adapt to changing demand patterns. This approach works effectively with all three compression technologies, though implementation details vary by manufacturer and specific model.

Engage with Knowledgeable Suppliers

Partner with compressor suppliers demonstrating deep application knowledge and technical expertise across all available technologies. Look for manufacturers with a proven track record in your industry sector and inquire about references from similar installations. A collaborative approach to system design often yields the best efficiency results, leveraging supplier expertise to match the right technology—scroll, screw, or rotary tooth compression mechanism—to your specific application requirements.

Implement Proper Installation and Commissioning

Ensure new compressors are installed and commissioned by factory-trained technicians following manufacturer guidelines. Proper installation, including correct alignment, piping, and electrical connections, is essential for achieving rated efficiency performance regardless of the selected technology. Commissioning should include performance testing to verify the system meets specified efficiency targets before full implementation.

Develop a Preventive Maintenance Program

Implement a comprehensive preventive maintenance program based on manufacturer recommendations and operating conditions. Regular maintenance ensures continued efficiency while extending equipment service life and preventing costly breakdowns. Consider incorporating condition-based maintenance technologies to optimize maintenance intervals and reduce costs, with particular attention to the unique requirements of your selected compression technology—whether scroll, screw, or rotary tooth compression mechanism.

Conclusion: Strategic Implementation of Energy-Efficient Compression Technology

As industrial operations face increasing pressure to reduce energy consumption and environmental impact, selecting energy-efficient oil-free compressors has become a critical strategic decision. The 2025 regulatory landscape, with stricter MEPS standards and global energy management initiatives, further emphasizes the importance of optimizing compressed air systems.

Understanding the efficiency characteristics of available technologies—including scroll type air compressors, screw compressor technology, and the innovative rotary tooth compression mechanism—enables industrial buyers to make informed decisions balancing performance requirements with energy conservation goals. Integrating smart monitoring systems, variable speed drives, and advanced control algorithms further enhances efficiency by ensuring optimal operation under varying demand conditions.

Case studies and practical guidelines demonstrate that significant efficiency improvements are achievable through modern oil-free compressor technology. While initial investment may be higher than conventional equipment, resulting energy savings, improved reliability, and reduced environmental impact typically yield attractive returns on investment.

As the industrial sector continues evolving toward greater sustainability, the role of energy-efficient compressed air systems will only grow in importance. Staying informed of technological advancements, regulatory requirements, and best practices allows industrial buyers to position their operations for long-term success in an increasingly competitive and resource-constrained global marketplace.

When evaluating specific oil-free compressor solutions, consider manufacturers with proven technical expertise and demonstrated commitment to innovation across all available technologies. Companies that have achieved significant technological breakthroughs in oil-free compression and maintain industry-leading certifications offer compelling options for industrial buyers seeking to optimize both efficiency and air quality in their compressed air systems, regardless of whether scroll, screw, or rotary tooth technology best matches their application requirements.