In the food processing industry, where consumer safety and product integrity are non-negotiable, compressed air systems represent a critical yet often undervalued component of quality assurance. As an industry specialist with over 15 years of experience implementing air quality solutions, I've witnessed firsthand how compromised compressed air can undermine even the most rigorous production standards. This technical case study examines how a leading food processing facility specializing in ready-to-eat meat products achieved remarkable quality improvements and regulatory compliance by implementing TÜV Class O certified oil-free compressors, resulting in measurable business benefits and enhanced brand reputation.

The Critical Role of Compressed Air in Food Manufacturing

Compressed air serves as the "fourth utility" in modern food processing facilities, powering everything from product conveying and packaging systems to automated cleaning and agitation processes. In many applications, this compressed air comes into direct or indirect contact with food products and their immediate environment, making air quality a critical control point for food safety management systems.

Industry research consistently identifies compressed air as a potential vector for product contamination, with oil carryover from lubricated compressors representing one of the most significant risks. Even minute quantities of oil aerosols and vapors can compromise product integrity, leading to off-flavors, shortened shelf life, and potential health hazards for consumers. For food processors, the financial implications are staggering—a single contamination incident can result in recall costs exceeding $1 million, not including the incalculable damage to brand reputation and consumer trust.

Against this backdrop, oil-free compressor technology has emerged as the gold standard for mitigating contamination risks. The global market for oil-free compressors in food applications is projected to grow at a 6.6% compound annual rate through 2035, reflecting the industry's increasing recognition of air quality as a strategic production parameter rather than merely an operational consideration.

Understanding TÜV Class O Certification and ISO 8573-1 Standards

When evaluating oil-free compressor technologies, understanding the rigorous standards that define true air purity is essential. TÜV Class O certification represents the highest level of assurance available for oil-free compressed air systems, going beyond basic industry standards to provide absolute confidence in contamination control.

Unlike generic "oil-free" claims that may only address liquid oil carryover, TÜV Class O certification requires comprehensive testing for all forms of oil contamination—including aerosols, vapors, and liquids—across a range of operating conditions. The certification process involves:

- Rigorous performance testing under varying temperatures and pressures

- Comprehensive analysis of all potential oil pathways within the compressor system

- Verification of zero detectable oil in the final compressed air stream

- Ongoing monitoring requirements to maintain certification status

This certification aligns with ISO 8573-1, the international standard that establishes purity classes for compressed air based on three primary contaminants: solid particles, water, and oil. While the standard defines multiple purity classes, Class 0 represents the most stringent category, indicating that the compressor itself contributes no measurable oil contamination to the air stream.

For food processing applications, this translates to compressed air with total hydrocarbon content ≤0.01 mg/m³—100 times stricter than lower purity classes. This level of contamination control is particularly critical for sensitive applications such as ready-to-eat products, dairy processing, and beverage bottling, where even trace contamination can have severe consequences for product quality and consumer safety.

The Technical Challenge: Persistent Contamination Issues in a Leading Facility

Our case study focuses on a prominent food processing plant producing over 50,000 metric tons annually of ready-to-eat meat products—a category with particularly stringent safety requirements. Despite operating conventional oil-flooded screw compressors with multiple filtration stages, the facility faced persistent quality challenges that threatened its market position and regulatory compliance.

Product quality audits consistently identified two critical issues directly linked to compressed air quality:

- Microbial Contamination: Regular detection of aerobic bacteria in finished products at levels approaching regulatory limits, necessitating costly reprocessing and increased testing frequency

- Visual Defects: Occasional presence of microscopic oil droplets on product surfaces, leading to customer complaints and brand reputation concerns

Root cause analysis traced these issues to fundamental limitations in the facility's compressed air system. Despite regular maintenance, the system struggled to maintain consistent air quality due to:

- Variable pressure drops across filtration stages creating inconsistent protection

- High maintenance requirements leading to occasional filter change delays

- Inability to effectively remove oil vapors that could condense on cold product surfaces

- Microbial growth in moisture-trapping areas of the compressed air distribution system

The facility's quality management team recognized that incremental improvements to their existing filtration system would be insufficient to achieve their aggressive quality improvement targets. A fundamental rethinking of their approach to compressed air generation was required.

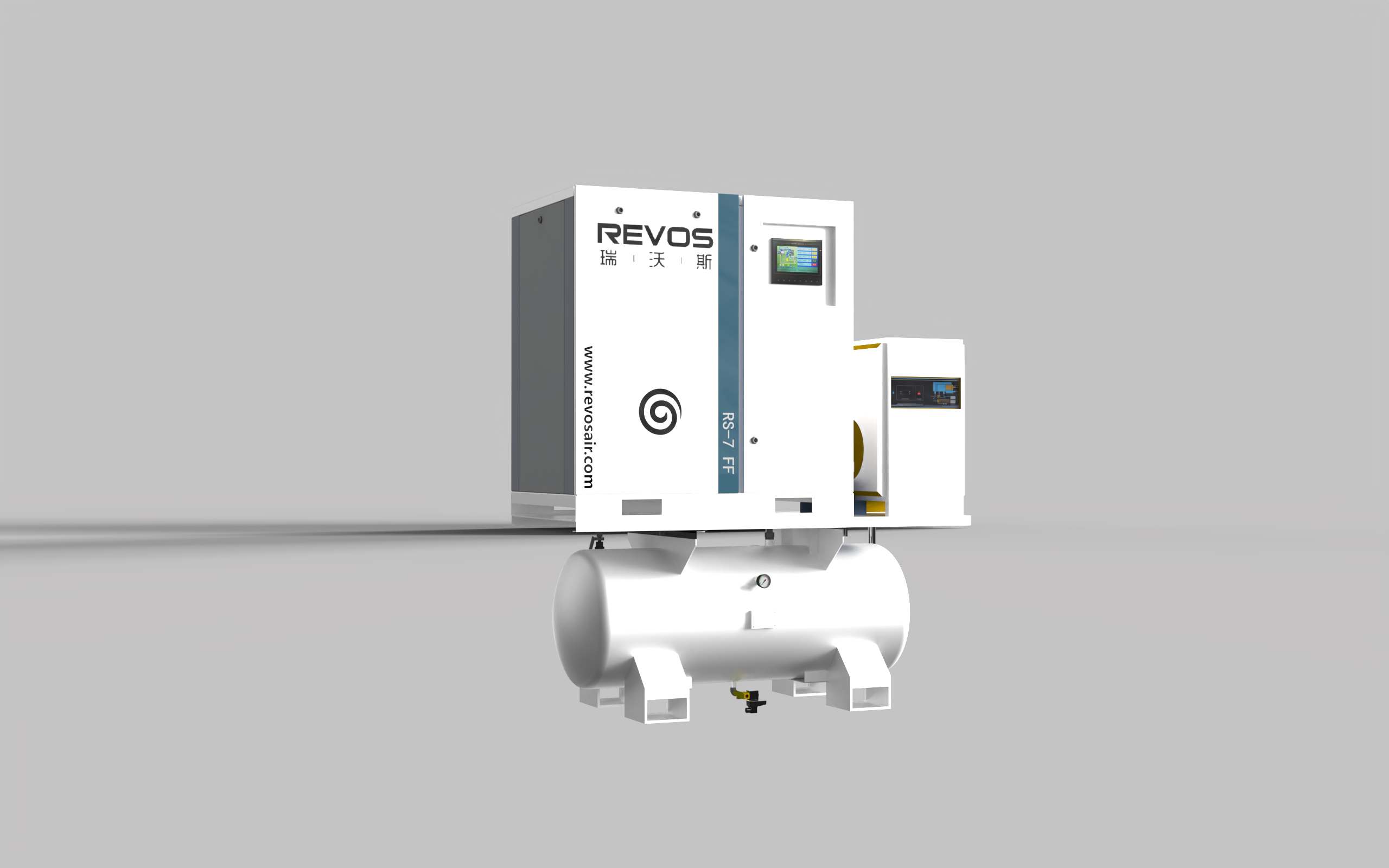

Technology Solution: Implementing Revos TÜV Class O Certified Compressors

After a comprehensive evaluation of available technologies, the facility selected Revos rotary tooth oil-free compressors, which had recently achieved TÜV Class O certification (ISO 8573-1 Class 0). This decision was based on several key technical advantages offered by Revos technology:

Rotary Tooth Compressor Technology

Revos' innovative rotary tooth design represents a significant advancement in oil-free compression technology. Unlike traditional screw compressors that require complex oil-injection systems for sealing and cooling, the rotary tooth design uses precision-engineered cast iron teeth that maintain minimal clearance without lubrication. This design eliminates the primary source of oil contamination while offering several performance benefits:

- Continuous Compression Process: The intermeshing tooth profile creates progressively smaller compression chambers, resulting in smoother airflow and lower pressure fluctuations compared to piston compressors

- Enhanced Heat Dissipation: Cast iron construction provides superior thermal conductivity, reducing operating temperatures and improving efficiency

- Reduced Vibration and Noise: Balanced rotating components result in significantly lower vibration levels (≤75 dB) compared to traditional oil-free technologies, reducing noise pollution in the production environment

Scroll Compressor Innovation for Critical Applications

Complementing the rotary tooth compressors for general plant air, the facility implemented Revos scroll compressors for their most sensitive applications, including product packaging and surface cleaning. Scroll technology offers unique advantages for these critical operations:

- Hermetic Design: Fully enclosed compression chamber eliminates potential contamination pathways

- Oil-Free Operation: Orbiting scroll motion requires no lubrication within the compression chamber

- High Air Quality: Near-constant temperature compression minimizes moisture issues and microbial growth potential

This combination of technologies provided the facility with a comprehensive compressed air solution tailored to their specific contamination challenges while delivering improved energy efficiency compared to their previous system.

Implementation Process and Quality Improvement Results

The implementation followed a systematic approach designed to minimize production disruption while ensuring comprehensive contamination control:

- System Design Phase: Detailed air audit mapping usage patterns and contamination risk points throughout the facility

- Phased Installation: Strategic implementation of three Revos RM series compressors during scheduled maintenance periods

- Distribution System Upgrade: Installation of stainless steel piping with optimized slope to eliminate moisture traps

- Validation Testing: Comprehensive air quality testing at all critical use points following ISO 8573 methodologies

- Staff Training: Operator training program focused on maintenance requirements and air quality monitoring

Implementation results exceeded the facility's quality improvement targets, with measurable benefits appearing within the first three months of operation:

- 72% Reduction in Microbial Contamination: Aerobic bacteria counts in finished products decreased by 72%, with all samples now consistently testing well below regulatory limits

- Complete Elimination of Visual Defects: Oil-related surface contamination was eliminated, resulting in zero customer complaints related to product appearance

- 40% Reduction in Maintenance Costs: Simplified filtration requirements and extended service intervals reduced compressed air system maintenance expenses by 40%

- 15% Improvement in Energy Efficiency: Specific energy consumption for compressed air generation decreased by 15%, delivering annual energy savings of approximately 80,000 kWh

Most significantly, the implementation of TÜV Class O certified compressors provided the facility with a marketable quality advantage. During a subsequent third-party audit for a major retail customer, the compressed air system received special recognition for exceeding industry best practices, resulting in expanded business opportunities with premium retailers.

Industry Implications and Emerging Trends

This implementation success offers valuable insights for food processors facing similar quality challenges while reflecting broader trends in the compressed air industry. As regulatory requirements and consumer expectations continue to rise, adopting TÜV Class O certified compressors is evolving from a compliance measure to a strategic differentiator.

Market data supports this trend, with the global oil-free compressor market projected to reach $7.62 billion by 2033, growing at a 6.6% compound annual rate. Within the food processing sector specifically, adoption rates are even higher, driven by:

- Increasing regulatory scrutiny of indirect food contact surfaces

- Growing consumer awareness of food safety issues

- Advancements in oil-free technology making these systems more cost-competitive

- Total cost of ownership advantages through reduced maintenance requirements

Looking ahead, several technological developments will further enhance oil-free compressor performance and cost-effectiveness:

- Smart Monitoring Systems: Integration of IoT sensors for real-time air quality monitoring and predictive maintenance

- Energy Recovery Systems: Advanced heat recovery technologies capturing waste heat for facility heating applications

- Material Science Innovations: New composite materials offering enhanced durability and performance in oil-free designs

- Variable Speed Technology: Precision control matching air production to demand for maximum energy efficiency

For food processors evaluating compressed air system upgrades, the critical insight is recognizing compressed air as a strategic component of quality management rather than merely an operational utility. As demonstrated in this case study, investing in TÜV Class O certified technology delivers measurable returns through improved product quality, reduced waste, and enhanced brand reputation.

Conclusion: The Strategic Value of TÜV Class O Compressors in Food Processing

This case study demonstrates the transformative impact of implementing TÜV Class O certified oil-free compressors in food processing environments. By eliminating the root cause of oil contamination and significantly reducing microbial risks, the facility achieved substantial quality improvements that directly contributed to business performance and market differentiation.

Three critical lessons emerge for food processing facilities evaluating compressed air systems:

- Air Quality as a Strategic Asset: Superior compressed air quality can be leveraged as a competitive advantage in the marketplace, particularly when targeting premium retail channels with stringent quality requirements

- Total Cost of Ownership Perspective: While oil-free compressors may represent a higher initial investment, maintenance, filtration, and quality-related cost savings typically deliver positive returns within 2-3 years

- Certification Matters: Not all "oil-free" compressors are created equal—TÜV Class O certification provides independent verification of performance claims and ensures consistent quality over the equipment lifecycle

As food safety regulations evolve and consumer expectations rise, robust contamination control measures will only grow in importance. The implementation success documented in this case study provides a compelling model for other food processing facilities seeking to enhance their quality assurance capabilities while improving operational efficiency.

For industry professionals evaluating their compressed air systems, the key recommendation is to conduct a comprehensive air quality audit that maps contamination risks throughout the production process. This assessment should consider current regulatory requirements, future quality objectives, and market positioning strategies—ultimately recognizing that in today's competitive food processing landscape, air quality represents both a potential risk and a significant opportunity for differentiation.