In the beverage production industry, maintaining absolute product purity while meeting increasingly stringent regulatory standards presents significant challenges. As a seasoned industry professional with over a decade of experience implementing compressed air solutions in food and beverage facilities, I've seen firsthand how contamination risks can compromise product integrity and brand reputation. This case study examines how a mid-sized beverage bottling plant eliminated persistent contamination issues by implementing oil-free scroll compressor technology, resulting in improved product quality, regulatory compliance, and operational efficiency.

The Challenge: Hidden Contamination Threats in Beverage Production

The beverage facility in question produces approximately 50,000 bottles daily of carbonated soft drinks and bottled water. They faced recurring problems with particulate and oil contamination in their compressed air system—a critical component in beverage production air systems. Despite using traditional oil-lubricated compressors with multi-stage filtration, quality control inspections consistently detected trace oil contaminants exceeding 0.01 mg/m³—well above the 0.003 mg/m³ limit specified by their quality assurance program.

The Cost of Compromised Air Quality

Contamination issues appeared in several critical production areas:

- Product Rejection: About 1.2% of finished products showed visible particulate matter in bottles, resulting in monthly losses exceeding $15,000

- Equipment Downtime: Pneumatic valves and filling machines needed frequent cleaning and maintenance, causing production interruptions averaging 4 hours weekly

- Regulatory Concerns: Tighter food safety regulations, including 2025 updates to Global Food Safety Initiative (GFSI) standards, created uncertainty about future compliance

- Quality Assurance Burden: Enhanced testing protocols consumed 15% of QA department resources

The plant utilized compressed air across multiple production stages: bottle cleaning, filling, capping, and labeling. Each application presented unique contamination risks, especially direct air contact during bottle rinsing before filling—making food grade compressor applications essential for maintaining product integrity.

The Solution: Implementing Oil-Free Scroll Compressor Technology

After a comprehensive system audit, the facility's engineering team partnered with a compressed air specialist to install an oil-free scroll compressor solution. Several key factors influenced this decision:

Technology Selection Criteria

- Air Quality Requirements: Need for ISO 8573-1 Class 0 certification for oil-free air to eliminate contamination risks

- Energy Efficiency: Facility sustainability goals targeting 20% reduction in energy consumption

- Space Constraints: Limited floor space in the existing compressor room

- Operational Continuity: Minimal downtime during installation and transition

- Total Cost of Ownership: Long-term reliability and maintenance considerations

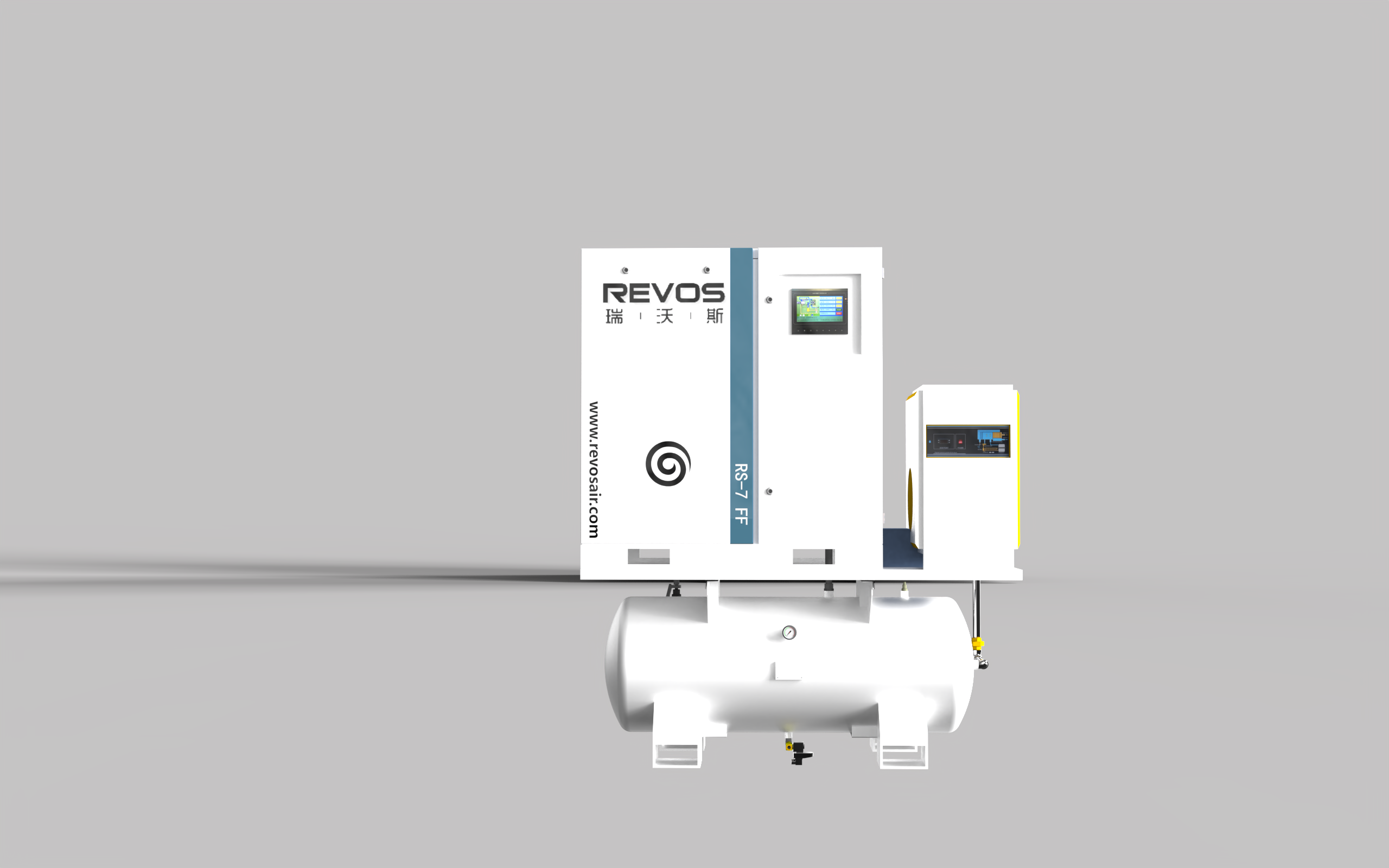

The selected solution featured three Revos oil-free scroll compressors (model RS-37) with integrated drying systems, providing 110 kW total capacity. These units were chosen primarily for their German TÜV Class 0 certification (ISO 8573-1 Class 0), confirming zero oil content in the compressed air stream—making them ideal for sanitary air compressor solutions in food and beverage applications.

Technical Advantages of Scroll Compressor Design

Oil-free scroll compressors operate through orbital motion of two interlocking spiral scrolls—one fixed and one orbiting—that compress air without metal-to-metal contact. This design eliminates the need for lubrication in the compression chamber, addressing the root cause of oil contamination. Additional benefits included:

- Lower Energy Consumption: Variable speed drive technology matched air output to demand, reducing energy waste

- Reduced Maintenance: Fewer moving parts than traditional screw compressors minimized service requirements

- Quieter Operation: Sound levels below 72 dB eliminated need for additional noise dampening

- Compact Footprint: Vertical design required 35% less floor space than the previous system

Implementation Process: Minimizing Disruption During Transition

The implementation followed a phased approach to ensure continuous production during transition:

Phase 1: System Design and Planning (2 weeks)

- Detailed air demand analysis across all production lines

- Piping layout optimization to minimize pressure drops

- Electrical system assessment and upgrades

- Development of contingency plans for production continuity

Phase 2: Installation and Commissioning (5 days)

- Installation of new compressors and drying equipment

- Integration with existing air distribution system

- Performance testing and optimization

- Staff training on new system operation

Phase 3: Monitoring and Fine-Tuning (4 weeks)

- Continuous air quality monitoring

- Performance optimization based on production patterns

- Adjustment of maintenance schedules

- Documentation for regulatory compliance

The entire transition completed with only 8 hours of unplanned production downtime—significantly below the projected 24 hours.

Results: Quantifiable Improvements Across Operations

Within three months of implementation, the facility documented substantial improvements across key performance metrics:

Contamination Elimination

- Oil Content: Consistent measurement of 0.000 mg/m³ (non-detectable) in compressed air

- Particulate Matter: Reduction from 0.12 mg/m³ to 0.005 mg/m³, exceeding ISO 8573-1 Class 1 standards

- Product Rejection Rate: Decrease from 1.2% to 0.15%, resulting in annual savings of approximately $162,000

Operational Efficiency

- Energy Consumption: 18% reduction in compressed air system energy usage, translating to $42,000 annual savings

- Maintenance Costs: 32% decrease in maintenance expenses due to reduced filter changes and equipment servicing

- Downtime: 75% reduction in production interruptions related to compressed air issues

Compliance and Quality Assurance

- Regulatory Compliance: Full compliance with 2025 GFSI standards and ISO 22000 requirements

- QA Efficiency: 40% reduction in time spent on compressed air quality testing

- Documentation: Automated data logging simplified regulatory reporting

Lessons Learned: Key Considerations for Beverage Producers

This food industry air compressors case study highlights several critical insights for beverage production facilities considering compressed air system upgrades:

1. Address Contamination at the Source

Traditional oil-lubricated compressors with filtration systems can never achieve the same contamination control as true oil-free technology. The facility's experience showed filtration alone couldn't reliably meet quality requirements, while oil-free compressors eliminated the contamination source entirely.

2. Total Cost of Ownership Matters

While oil-free compressors represent a higher initial investment, the 2.3-year payback period in this case justified the expenditure through reduced waste, maintenance, and energy costs.

3. Phased Implementation Minimizes Risk

The structured approach to system transition ensured production continuity while allowing adjustments based on real-time performance data.

4. Certification Verification is Essential

Not all "oil-free" compressors are equal. The Revos units' TÜV Class 0 certification provided independent verification of performance claims, proving valuable during regulatory audits.

Conclusion: Investing in Air Quality for Long-Term Success

This beverage bottling facility's experience demonstrates the transformative impact of oil-free scroll compressor technology on product quality, operational efficiency, and regulatory compliance. By eliminating contamination risks at their source, the plant improved their bottom line and enhanced brand reputation for quality and safety.

For beverage producers facing similar challenges, the key takeaway is recognizing compressed air as a critical component of product quality rather than merely an utility. As regulatory requirements evolve and consumer expectations rise, investing in oil-free compressed air technology represents a proactive strategy for long-term success in the competitive beverage industry.

Based on industry best practices and this case study experience, beverage facilities should conduct comprehensive compressed air audits every 2-3 years to evaluate contamination risks and efficiency opportunities. Such proactive assessments often reveal hidden improvement potential that can significantly impact both product quality and operational performance.